Electromagnetic Shielding Products (EMI/RF)

All the EMI shielding components for your electronic projects

Each of our Electromagnetic Shielding Products (EMI/RF) can be customised on request to fit in with your electronic project.

Conductive gaskets | On-board shielding | SMD inserts | Spring contacts | EMI shielding windows| EMI and RF absorbers

Few words about Electromagnetic Compatibility (EMC):

Electromagnetic Shielding and Sealing (EMI/RF)

The electromagnetic compatibility (EMC) is the ability for an equipment to work without generating or undergo electromagnetic interferences or disturbances.

Electromagnetic Interferences

Electromagnetic interferences might be generated by high tensions, radiofrequencies, or thunder for example. Several normes certify the ability for an equipment to be compliant.to electromagnetic interferences (EMI).

The electromagnetic interferences are transmitted from one electronic device to another by radiation or conduction through printed circuit track or connectors (PCB).

The necessity to master the electromagnetic compatibility of the equipment

Every systems are exposed to magnetic fields (low frequencies) and electromagnetic fields (high frequencies). All is a mater of measure and control. The level of electromagnetic compatibility must comply to local and international legislation. The equipment must be functional without disturbing close electronic equipment.

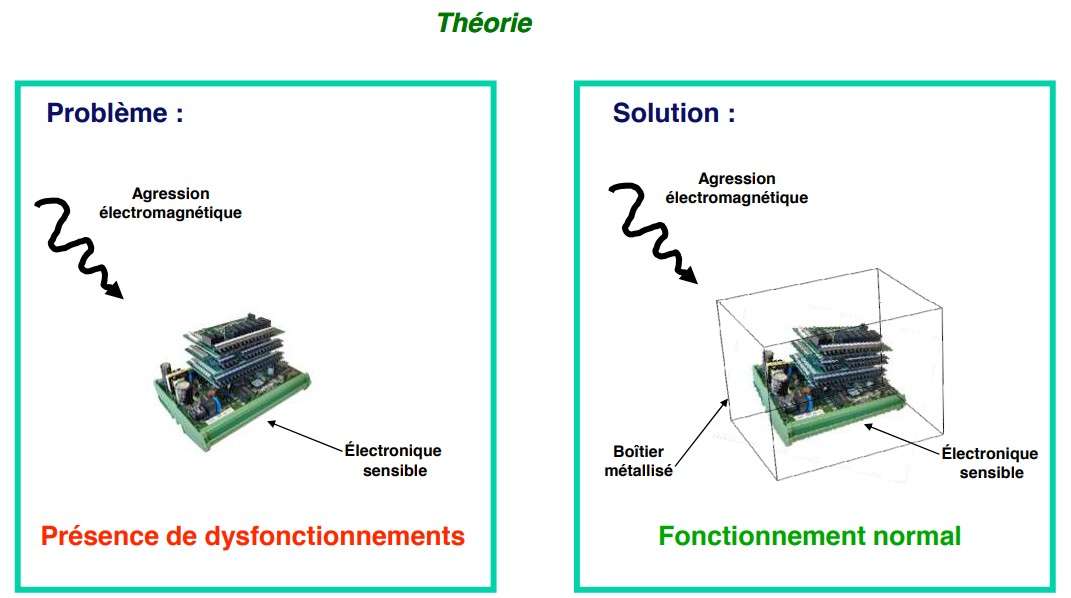

Without taking into account the electromagnetic compatibility (EMC) these electromagnetic perturbations can lead to major dysfunctions or general failures on complete installations. For example, in the industrial sector. The presence of electronic equipment subject to electromagnetic interferences means that the constraints in terms of electromagnetic compatibility must be seriously taken into account both at the component level and at the equipment level.

A strongest security against electromagnetic interferences (EMI) is required in control and measurement installations. the main goal is to minimize the radiation and thus prevent interference with other areas or equipment.

Application Field of Electromagnetic Compatibility (EMC)

Every fields are concerned by the Electromagnetic Compatibility (EMC). Compelma team is working every day on worldwide electromagnetic projects. As defence, aerospace, IT, telecommunications, medical and industrial.

How does Compelma work on your Electromagnetic Compatibility (EMC) Projects?

Compelma engineers have an extensive background on electromagnetic compatibility (EMC) projects, especially for each kind of field and industry. Compelma handles the protection against EMI and RF on your electronic project. Our goal is to let you concentrate on your activity and your add value. Compelma makes you earn time and costs, for a better efficiency on your projects.

Electromagnetic Shielding (RFI/EMI)

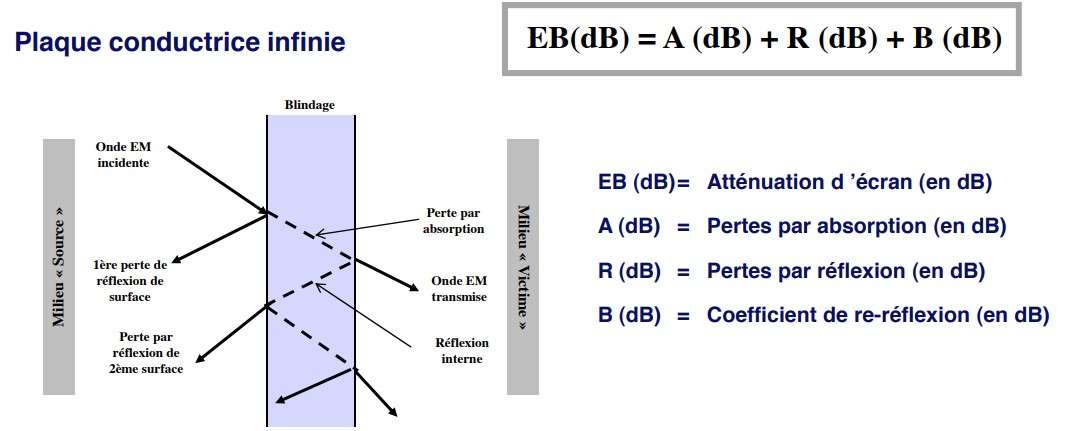

Electromagnetic shielding is mainly used to protect electronic equipment from electronic parasites and radiofrequencies interferences. The electromagnetic shielding is based on the Faraday cage principle. The goal is to reflect electromagnetic fields or to absorb these EM waves.

Principle of the Electromagnetic Shielding (EMI, RFI)

How to Choose the Correct Technology for Electromagnetic Compatibility (EMC)

Compelma advise you to about the best material and design for each setup and configuration, for an efficient electromagnetic shielding. These EMC/RF shielding products avoid that the electromagnetic fields, enter or leave a specific equipment.

Example of an Electromagnetic Shielding (EMC)

For example, in the case of a microwave, the mesh laminated with the window blocks the electromagnetic waves that heat the food. Light waves, with a shorter wavelength, pass through the mesh (even if it is also electromagnetic waves).

A Complete Setup for Electromagnetic Shielding

Compelma ensures a complete providing of your electromagnetic shielding setup. The EMI shielding of the electrical circuit and the sealing (EMC and IP). The electromagnetic shielding of your electronic equipment is tailor made by Compelma for the highest efficiency and by taking in account :

– The material compatibility (soldering compatibility and galvanique couples)

– Use and environment constraints

– Mechanical strengths and constraints (load, assembly process, fixation, dimensions, tolerances, weight…)

– Material and process costs

Concretely, What are the Solutions for Electromagnetic Compatibility (EMI and FR)

Compelma provides different EMI/RF products (standard or custom) depending on your specifications. Each project is studied to choose the best technologies and products for your electromagnetic problematics.

To isolate and protect electronic components and openings:

– EMI/RF Cover and Frame, custom or tailor made

– Mesh for ventilation opening

– Conductive foil and mesh

– Copper Mesh film

To absorb electromagnetic waves by Joule effect:

– EMI/RF absorbers (Ferrites and Loaded Foam)

– Loaded elastomers and Silicons (extruded, cut, molded)

For connection and grounding:

– Spring finger contacts (SMT)

– Metallic gaskets

For EMI ad IP sealing:

– Wire oriented silicone

– Loaded silicone gasket

– Bi-material gasket (silicone and loaded silicone)

Integration of Electromagnetic Shielding

We strongly advise to think about the electromagnetic compatibility (EMC) at the beginning of any electronic project. Electromagnetic interferences are often observed and measured too late during the conception of electronic products. A product blocked for commercialization just after the final electromagnetic tests is really expensive and penalazing.

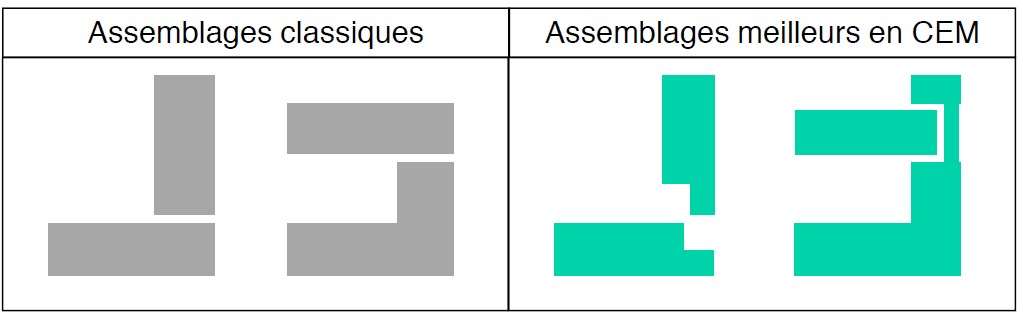

Good Practices for Electromagnetic Compatibility on Electronic Assembly

Few good practices must be applied during the complete conception process.

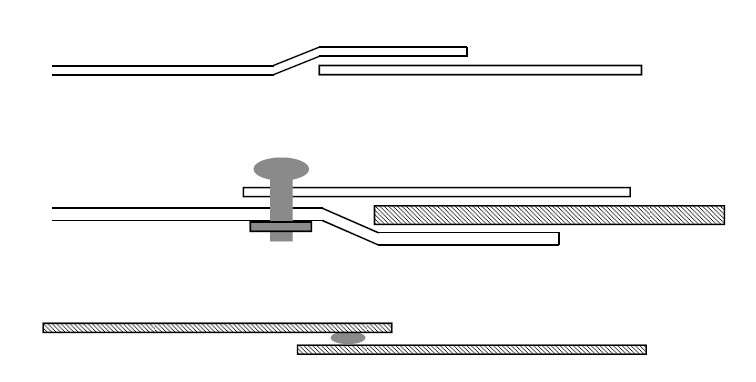

Deflectors / Chicane to Prevent Electromagnetic Leaks

Using chicanes for assembly to get the larger cover surface between two elements.

How to Assemble Partition to avoid Electromagnetic Leaks

the same logic is to apply for assembly between partition. The contact must be maximal between the two parts of the assembly. It helps to contain electromagnetic waves.

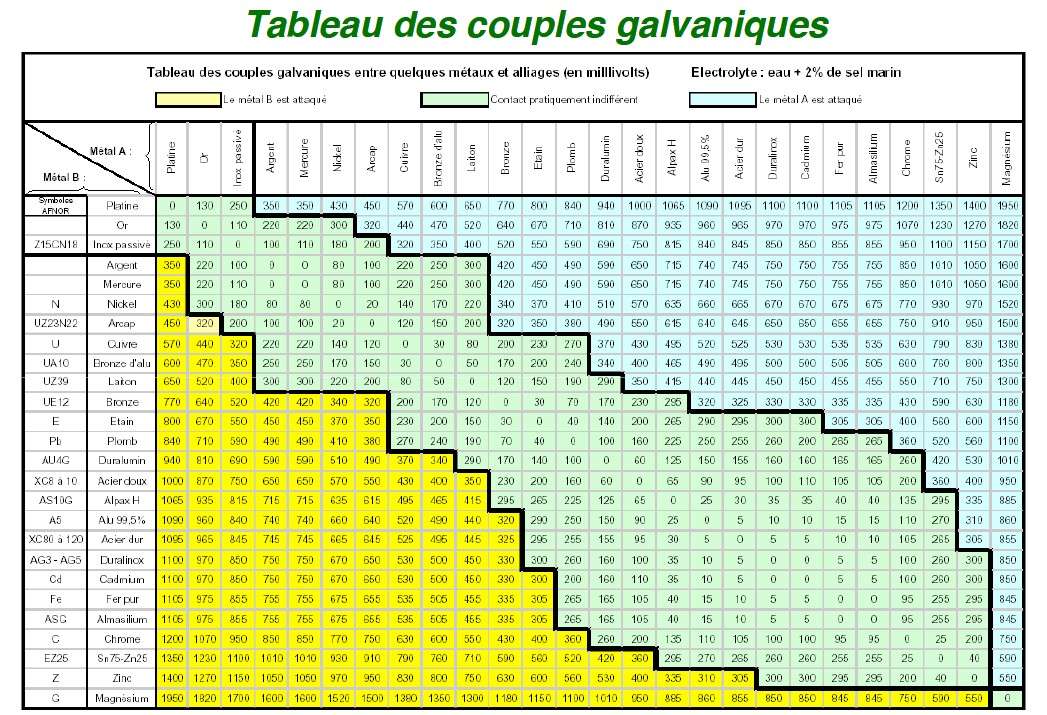

Galvanic Couples and Electromagnetic Compatibility (EMC)

Some equipment must work on harsh environment. With humidity for example. The sealing against electromagnetic interferences and fluid is ensured by specific gaskets.

Two different metals with an electrolyte (sea water for example) are working as a battery and will generate a small electrical power.

It might occurs a corrosion leading to diminution of the resistivity and so of the efficiency of the electromagnetic shielding.

Choosing the right material to minimize or avoid natural galvanic process is part of the Compelma expertise.

Gaskets for Electromagnetic Sealing

EMI and RF gasket integration must be anticipated as soon as possible. Indeed the grooves and fixation must be integrated to your electronic conception (especially for high IP sealing specifications).

Conductivity and Electromagnetic Compatibility

For the highest electromagnetic sealing performances, the grounding contact between mechanical element must be maximal. Compelma team searches and tests every day new technologies and material to keep you at the cutting edge of the technology. Our goal is to propose the materials with the highest conductivity to get the maximal EMI/RF shielding effect.

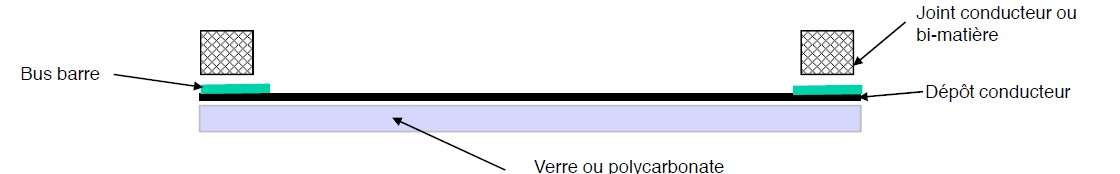

As Example, our team has develop a transparent Cu Mesh Film for electromagnetic shielding of windows. It is not an ITO film (the most common product with lower performances) but a photo-manufactured copper mesh. The final shielding product is more resistant (especially against oxydation) and conductive (conductivity of pure copper) than an ITO film.

Advices for Electromagnetic Compatibility Integration (EMC)

Our main goal at Compelma, is to advise you on your Electromagnetic Compatibility. for that, we used our technical knowledge and experience to secure your electronic project and developments against electromagnetic problematics.

A Question? A project? Please contact us using the tchat or our contact form. We are pleased to help you.

Now, about our products for EMI shielding:

Spring finger contacts (SMT)

Spring finger contacts (SMT) are used for connections in electronic assemblies (antenna, grounding, connection, assembly).

Their spring behaviour guarantees excellent resistance to vibration, even after tens of thousands of cycles.

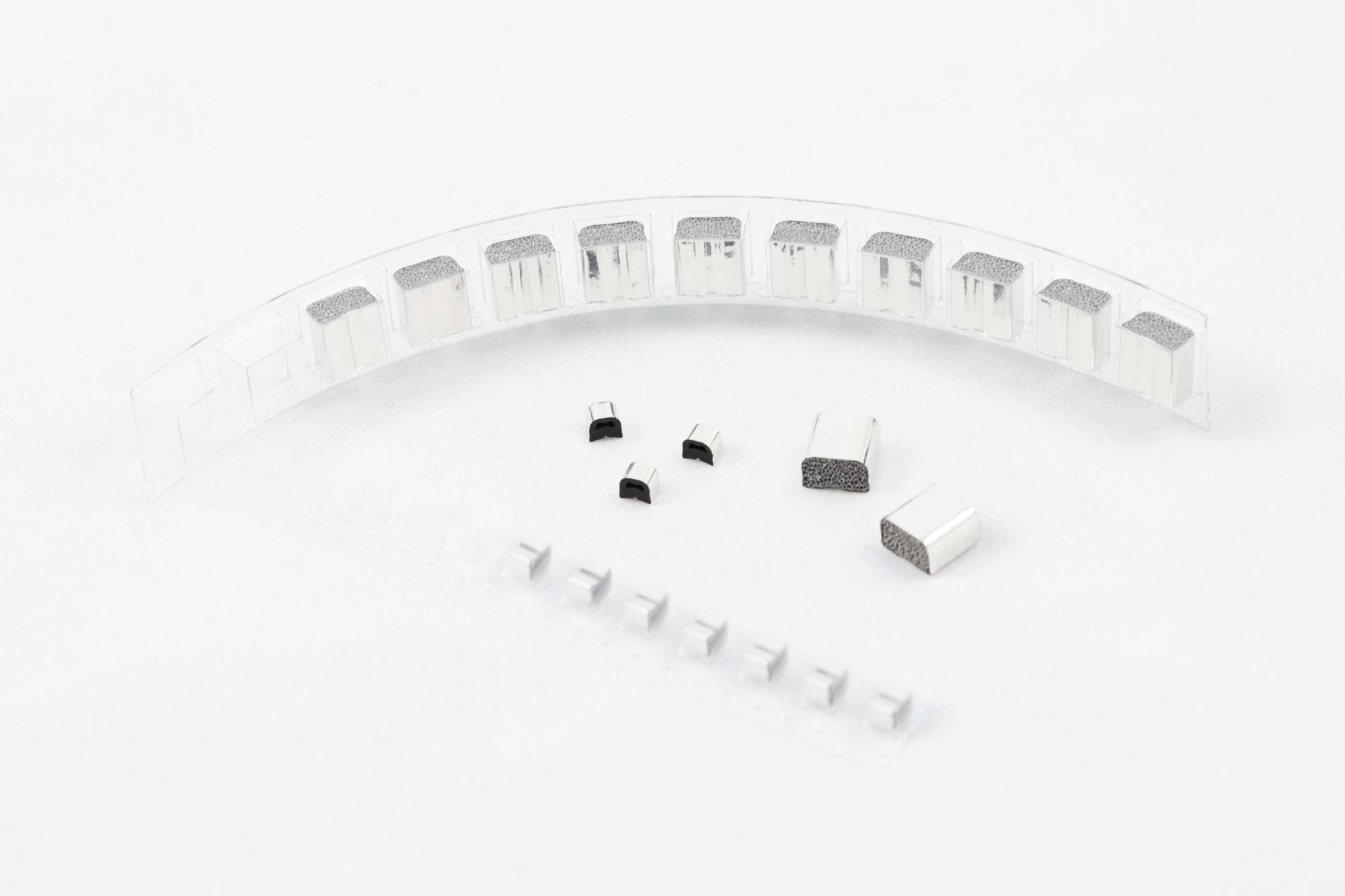

Soft SMD Contact Pads

Soft SMD contact pads are a competitive alternative to spring finger contacts as above.

They offer a higher compression range (>90%), a good resilience and a competitve price.

These SMD contacts are parkaged in reel for SMD assembly and are welded on PCB.

EMI shielding gaskets

Several conductive gasket technologies exist for EMI shielding and sealing. Each has its advantages and disadvantages.

Contact us to help you choose the right type of EMI gasket for your project.

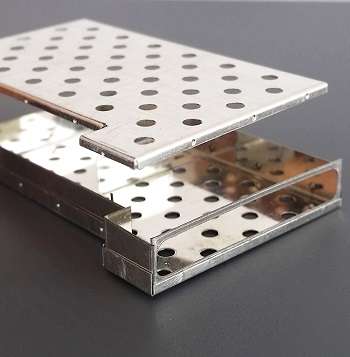

EMI shielding on-board (PCB)

EMI shielding covers are used to isolate sensitive components on electronic boards.

They can be soldered directly, or mounted using a belt or shielding clips.

Shaping by cutting and folding allows great design flexibility (openings, multi-cavities) at controlled costs.

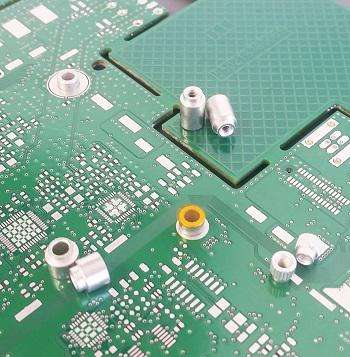

SMD Inserts

SMD inserts are used for electronic assembly and PCB complexing.

They can be deposited automatically (SMD) by gripping the kapton cover. These inserts are then soldered onto the board (push variants are available).

In addition to standard references, all dimensions and materials can be customised on request.

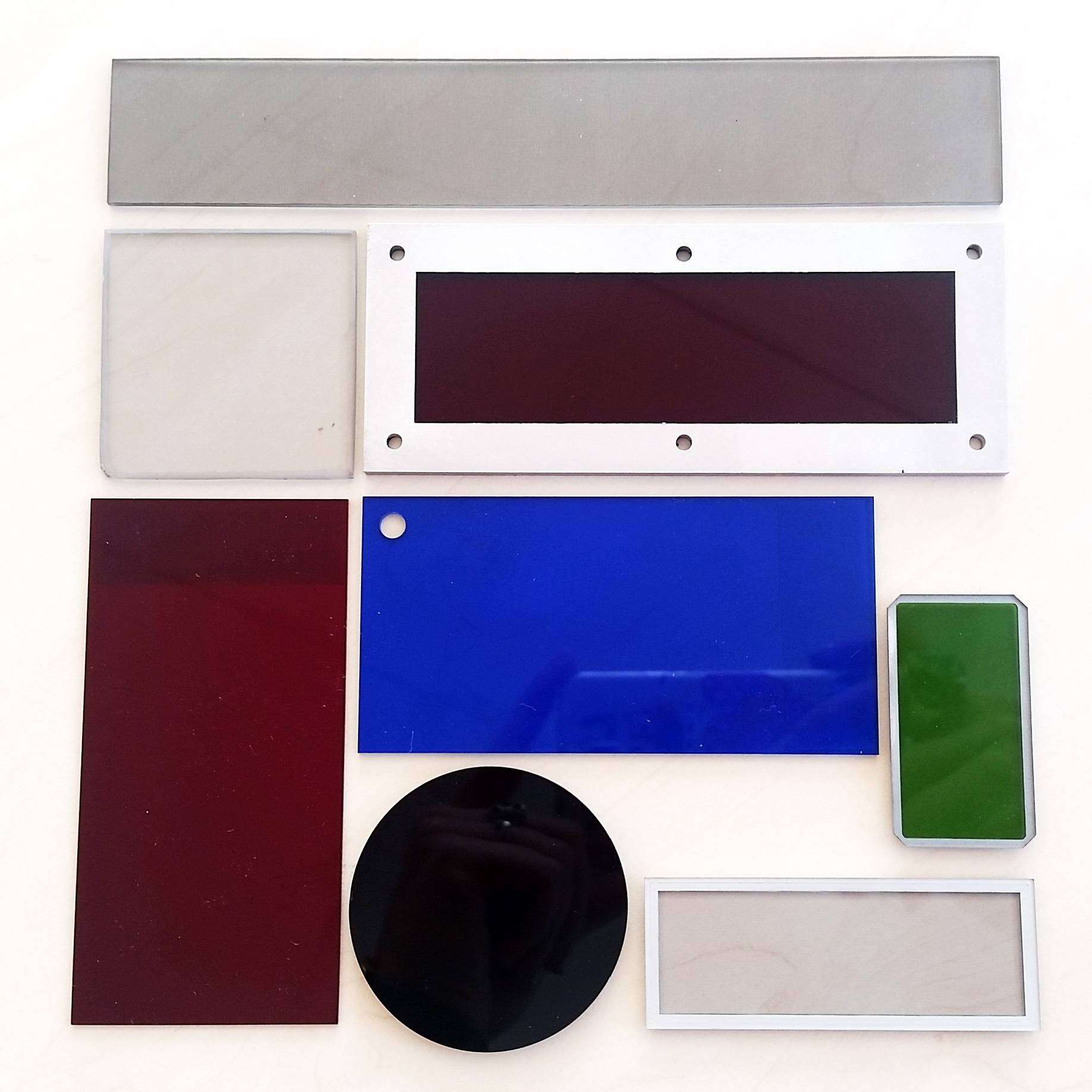

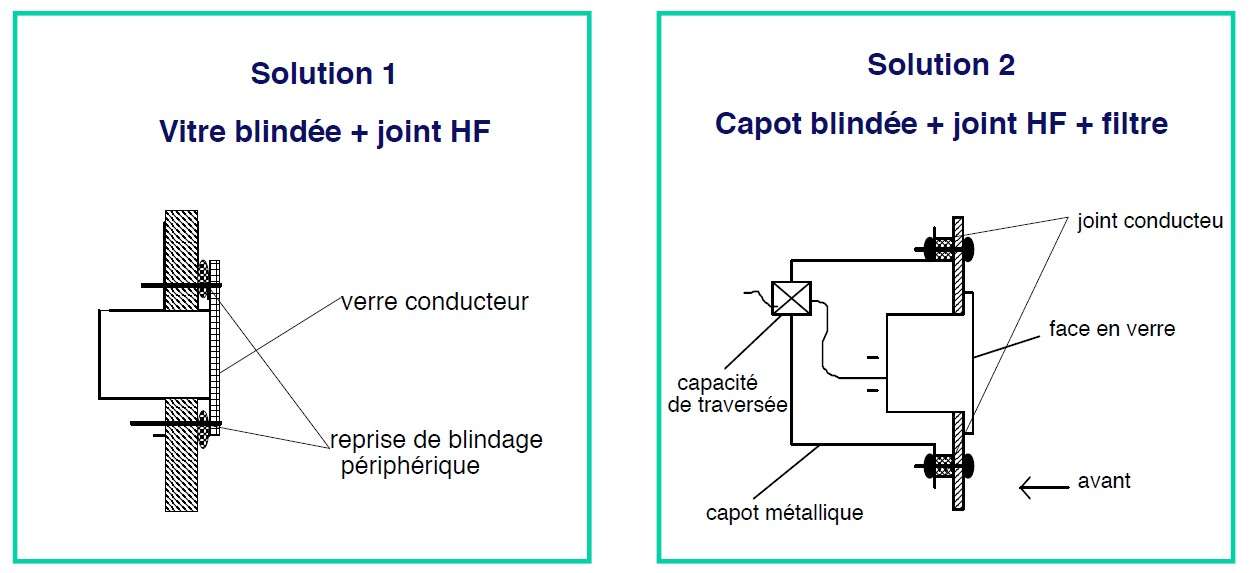

RF and EMI shielding windows

EMC and RF glass is conductive to provide a seal against RF and EM waves.

These panes can be moulded with a conductive mesh inside. Or a conductive film (Cu Mesh or ITO) can be laminated to the surface.

The overlay can be made of glass, polycarbonate or other materials. The level of shielding and transparency can be varied (depending on the mesh size of the conductive film or the ITO load).

Absorbent foams and ferrites (RF and EMC)

RF and EMI waves are absorbed by materials such as foam or ferrites. These RF and EMI absorbers dissipate the waves by the Joule effect.

They avoid all reflection and interference phenomena on metal surfaces.

Each absorber is specific to the frequency to be absorbed and the level of absorption expected.

We can help you choose and shape these EMI absorbers.