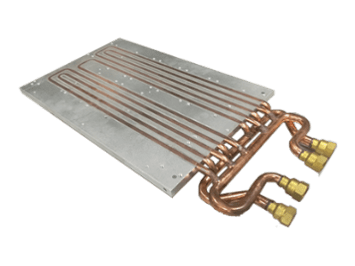

Cold plate for heat dissipation

Cold plates drain heat away from the electrical components and equipments

The fluid that circulates in the cold plates allows the heat to be drained away from the equipment. The materials and fluids used are adapted on a case-by-case basis depending on the power output.

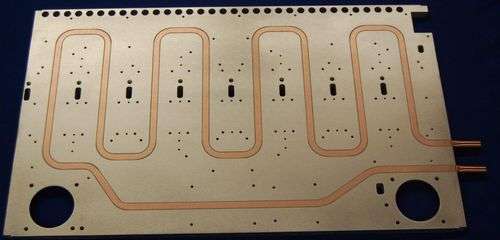

The cold plates for heat dissipation are made following your drawings. The components can be assembled on them or the plates can be assembled on the chassis to cool it.

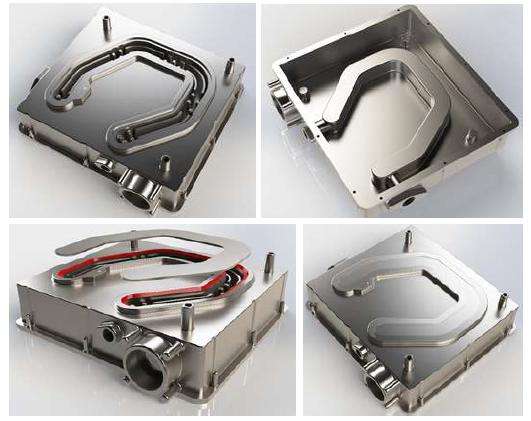

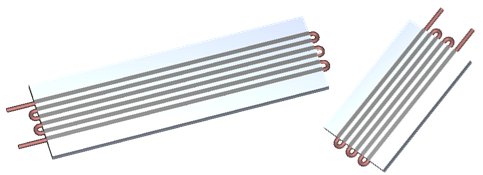

We can provide thermal studies to validate a design. We can also offer cost-effective alternatives to existing plates using other machining methods (laminated tubes, FSW, assemblies, etc).

Cold plates for Heat Dissipation, Key points :

- Thermal study on request

- Manufactured following your drawing

- Proposal of economical alternatives to existing plates

- Prototype to series production

We can advise you on the best practices for producing cold plates. In addition to feasibility studies, we can also provide thermal studies on request.

Description of cold plates for heat dissipation

A cold plate (also known as a cooling plate) is a metal plate in which a refrigerant (usually water) circulates. The fluid used will drain the heat from the components mounted on the cold plate to the outside of the system.

Heat transfer is forced by the fluid circulating in the cold plate (usually aluminium or copper), at medium or low pressure (atmospheric).

Cold plates are used for high power management and heat transfer. Particularly in high-performance computer applications or power applications. Cold plates are used for heat dissipation when air transfer is no longer sufficient or not possible to use.

All our cold plates for heat dissipation are made to measure according to your drawings and requirements.

You can find out everything there is to know about cold plates by reading our article on our website (in Resources): About cold plates.

You’ll learn how cold plates are integrated, how they’re designed, what their limitations are, and much more.