EMI Absorber

High frequency EMI absorber are foams and ferrites used for absorption and dissipation by joule effect of EMI and RF waves

Each EMI absorber is specific to a frequency range and absorption level. These EMI absorber neutralise the waves by dissipating them through the Joule effect (by releasing heat). In this way, they provide ‘clean’ environments by avoiding interference.

EMI absorber in the form of ferrites are used for RFID and microwave projects. They absorb a narrow frequency range.

EMI Foam absorber absorb wider frequency bands at higher levels. They take up more space. They are mainly used in anechoic chambers and EMC and RF test environments.

EMI Absorber and Microwave absorber, Key points :

- Special cuts and packaging (sheets, rolls) on request

- Thicknesses from 0.1mm to several tens of centimetres

- Wide catalogue of standard references available

- Can be laminated (multi-strips, strips, etc.)

We can advise you on the most suitable EMI absorber following your specifications and constraints (absorption, size, dimensions, etc.).

Prototypes and samples of EMI absorber on request.

Description of EMI and microwave absorber

Radio frequency (RF), microwave and electromagnetic EMI absorber are used for electromagnetic insulation and absorption of electromagnetic emissions by the Joule effect.

Different types of EMI absorber are available, from foam absorbers for wide-band absorption to thin elastomer-based absorbers that are frequency-calibrated (absorption over a reduced spectrum).

Our range is made up of EMI absorbers specific to each project. From RFID tag applications to anechoic chambers.

These EMI absorbers can be packaged in sheets or rolls. For prototyping as well as automated production lines.

All our microwave absorbers are RoHS and Reach compliant.

Sources of electromagnetic and radio-frequency interference controlled by microwave absorbents

There are two major causes of electromagnetic interference (EMI) and radio frequency interference (RFI) in electronic assemblies.

1) Miniaturisation and space reduction in electronic assemblies.

The proximity of electronic components in the same electronic assembly greatly increases the risk of interference and disturbance. However, this optimisation of space goes hand in hand with miniaturisation and is inevitable, even necessary, if we are to become more attractive and competitive.

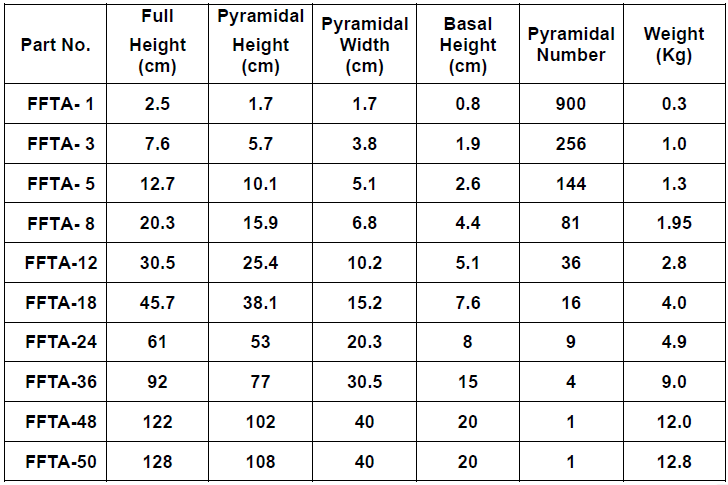

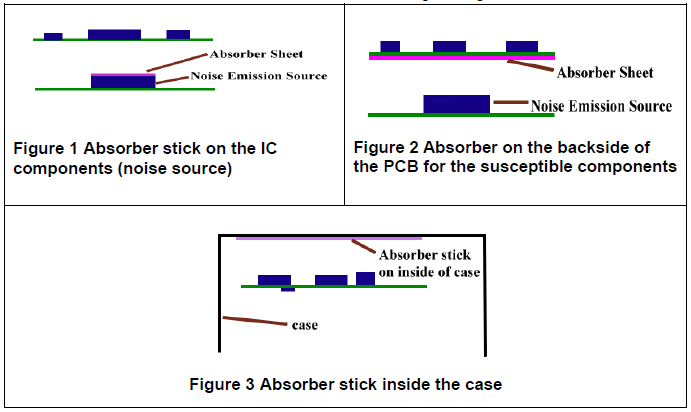

Microwave absorbers have their place in these complex assemblies to reduce disturbance by neutralising unwanted frequencies directly in the assemblies.

These microwave absorbers can be bonded directly to the components that emit the interference. They can also be bonded to sensitive components (antennas, sensors) to protect them from parasitic signals.

2) Radiation and electromagnetic noise transmitted by cables

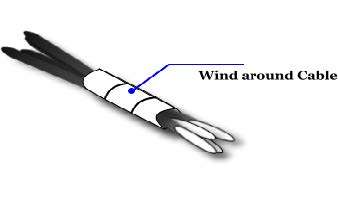

Parasitic noise can be generated by a module working at high power or high frequency (a CD read/write head, for example). This noise is then transmitted by the cables in the assembly.

To limit and absorb these frequencies, absorbers can be wrapped around sensitive cables. The electromagnetic disturbances are thus absorbed and neutralised by the absorbent material.

Why use a EMI or Microwave absorber?

EMI absorbers are an effective technological means of absorbing radio frequency emissions and reducing electromagnetic noise. These EMI absorbers make it possible to control parasitic signals and reduce the “Time-To-Market” by neutralising unwanted frequencies.

The fields of application for microwave absorbers are very varied. These EMI/RFI absorbers are used in cameras, mobiles, PCs, screens, etc.

These radio frequency absorbers are also widely used for RFID projects (125kHz, 13,56MHz and 800-900MHz). They drastically reduce interference with the surrounding metal environment (for example, they enable an RFID tag to be read at 80% of its nominal value on a metal surface).

Frequency ranges of RF and EM absorbers, from RFID to microwave frequencies:

Our range of microwave absorbents covers the following frequency ranges:

LF (Low frequencies): 30 to 300 kHz (RFID 125kHz, wireless charging, induction)

HF (High Frequencies): 3 to 30 MHz (RFID 13.56MHz, NFC)

VHF (Very High Frequencies): 30 to 300 MHz (radio)

UHF (Ultra High Frequencies): 300 to 1,000 MHz (RFID 800-900MHz, Lora, Sigfox, telecom including 5G from 600 to 700 MHz)

SHF (Super High Frequencies): 3 to 30 GHz (Telecom 5G 2.5/3.4GHz and 3.8/4.5GHz as well as 28 to 39GHz, Wifi 2.4-2.5GHz and 5GHz)

SHF includes the following bands: L (1 to 2GHz), S (2 to 4GHz), C (4 to 8 GHz), X (8 to 12 GHz), Ku (12 to 18GHz), K (18 to 27 GHz) and Ka (27 to 40 GHz).

Then the following ranges:

V band: 40 to 75 GHz

W band: 75 to 110 GHz

mm band: 110 to 30 GHz

For SHF and higher frequencies, metal surfaces offer relevant shielding (by skin effect). The question may arise of choosing a shielding cover rather than a microwave absorber.

Depending on the level of absorption required, the absorber can be very thin (0.1mm for a flexible ferrite sheet type absorber) or several tens of centimetres thick (for pyramid-shaped absorbing foams, for example).

Don’t worry, we’ll help you choose the microwave absorbent best suited to your application and your project.

You can already use the contact form or chat to discuss this. 🙂

How to choose the best absorbent for radio frequencies and electromagnetic fields

Ask yourself the following questions:

Where will the microwave absorber be applied?

In a room (such as an anechoic chamber): Flat or pyramid-shaped absorbent foams are preferable.

In a test box: flat absorbent foams take up less space.

For integration in electronic equipment: sheet absorbers such as ferrites or flat foams are preferable.

What is the main frequency to be absorbed (or frequency range)?

What level of absorption is required?

What are the space constraints?

Send us your answers in the chat, and we’ll give you our recommendations 🙂

What different types of EMI absorbents do we offer?

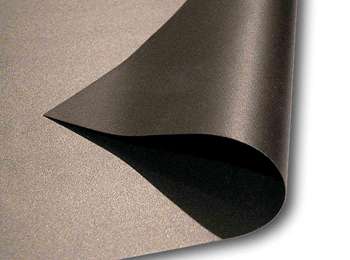

Sheet absorbents (flexible ferrite type) for microwave and microwave bands: COHTR and CORTS type absorbents

COHTR and CORTS type absorbents are EMI absorbents for targeted frequency bands ( on frequencies from RFID to microwave). These absorbers have absorption levels of around -5dB to-25dB, at frequencies between 10MHz and 77GHz.

Depending on the frequency range to be absorbed and the expected absorption level, the thickness varies from 0.1mm to 4mm.

Compelma can also design customised absorbers to suit specific applications (multi-band absorbers, laminates, etc.).

COHTR and CORTS microwave absorbers are effective in overcoming EMI/RFI/CEM problems in a wide range of equipment: Notebook, Wi-Fi equipment, RFID tags, 5G applications, etc.).

These absorbents can be packaged in sheets or rolls. We also have cutting tools (XY table and cutting press) to offer customised parts.

The recommended temperature range is -40°C to +120°C (over a short period of time). We recommend not exceeding +90°C for longer periods of time.

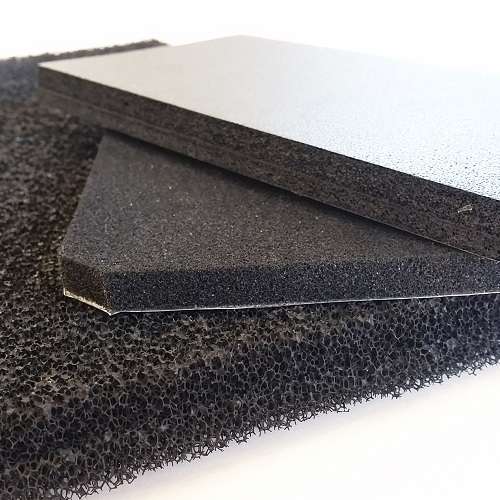

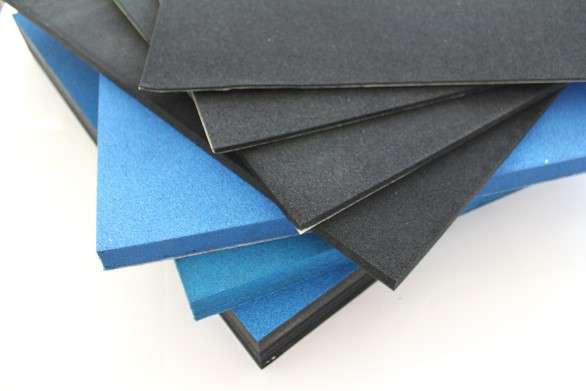

Flat foams, broadband radio frequency and microwave absorbers:

FFTF (single layer)

FFTM (multi-layer)

FFTF (single-layer microwave absorber) and FFTM (multi-layer microwave absorber) are polyurethane foams bathed in conductive carbon baths. These EMI absorbers are mainly used in anechoic chambers to protect radar antennas.

These radio frequency absorbing foams are available in several thicknesses. Higher thicknesses offer greater absorption performance. These EMI absorbent foams can be black (default) or painted blue on the surface.

These broadband absorbers are more effective when placed on a metal surface, so that the frequencies pass through the foam a 2nd time after reflection. These EMI absorbent foams can also be supplied with aluminium foil for better absorption of radio frequency (RF) and electromagnetic (EM) waves.

The recommended operating temperature is -30°C to 90°C maximum.

FFTF single-layer microwave (RF and EM) absorber foam specifications (more absorption data on request) :

FFTF-03 (Thickness: 0.3cm) for absorption of frequencies above 8GHz, down to -10dB

FFTF-04 (Thickness: 0.4cm) for absorption of frequencies above 6GHz, down to -10dB

FFTF-05 (Thickness: 0.5cm) for absorbing frequencies above 6GHz, down to -10dB

FFTF-06 (Thickness: 0.6cm) for absorption of frequencies above 3GHz, down to -10dB

FFTF-10C (Thickness: 1.0cm) for absorption of frequencies above 3GHz, down to -15dB

FFTF-15C (Thickness: 1.5cm) for absorption of frequencies above 2GHz, down to -20dB

FFTF-20 (Thickness: 2.0cm) for absorption of frequencies above 2GHz, down to -20dB

FFTF-30 (Thickness: 3.0cm) for absorption of frequencies above 2GHz, down to -25dB

FFTM multilayer microwave (RF and EM) absorber foam specifications (more absorption data on request) :

FFTM-15 (Thickness: 1.5cm) for absorption of frequencies above 3GHz, down to -15dB

FFTM-20 (Thickness: 2.0cm) for absorption of frequencies above 2.5GHz, down to -20dB

FFTM-25 (Thickness: 2.5cm) for absorption of frequencies above 2.5GHz, down to -20dB

FFTM-30 (Thickness: 3.0cm) for absorption of frequencies above 2GHz, down to -25dB

FFTM-60 (Thickness: 6.0cm) for absorbing frequencies above 1GHz, down to -30dB

These EMI absorbing foams are mainly supplied in 60cm x 60cm sheets. These EMI absorbers can be cut to size according to your drawings and specifications.

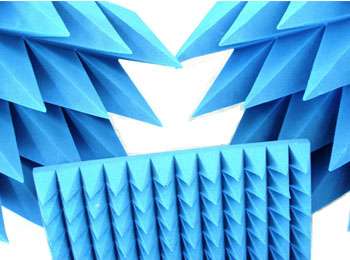

Pyramidal foams for broadband microwave absorption: FFTA

FFTA pyramid-shaped absorbent foams are polyurethane foams bathed in carbon baths to be loaded with conductive particles. These absorbing foams absorb microwaves over a very wide frequency band (from 80MHz to 60GHz). These absorbers are effective both for waves at normal incidence and those with angles of incidence.

Although they were initially designed for absorption from the front (on the cones). These microwave absorbers provide high dissipation of radiofrequency and electromagnetic waves on both the front and rear surfaces. For this reason, they are particularly suitable for applications in anechoic chambers or for covering test equipment or antennas in anechoic chambers.

FFTA absorbent foams are available in different thicknesses. You can therefore choose the most suitable absorbent depending on the absorption levels to be achieved and space constraints.

The standard dimensions of these absorbent foams are 60cm x 60cm. These EMI absorber can be cut to size and lined with aluminium foil for enhanced reflection through the foam.

The FFTA-36 and FFTA-50 pyramidal EMI absorber foams are particularly recommended for high-performance microwave antenna testing or for range testing of RCS equipment.

These microwave (RF and EM) absorbers are also widely used in semi-anechoic chambers that need to achieve NSA absorption levels of 4dB volumetric from 80MHz, and where high RF absorption is required.

In limited spaces, FFTA absorbent foams can be supplied in hybrid type for low-frequency absorption.

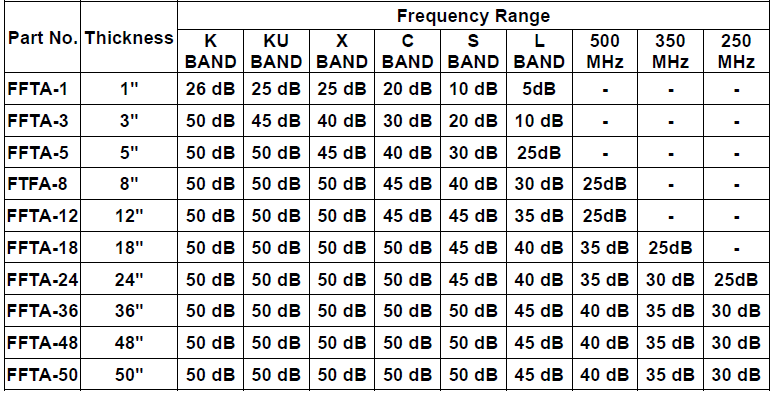

FFTA pyramidal microwave (RF and EM) absorber foam specifications (more absorption data on request) :

- FFTA-1 (Thickness: 1″) for absorption of K band to L band frequencies, down to -25dB

- FFTA-3 (Thickness : 3″) for frequency absorption from K band to L band, down to -50dB

- FFTA-5 (Thickness: 5″) for frequency absorption from K band to L band, down to -50dB

- FFTA-8 (Thickness: 8″) for frequency absorption from K band to 500MHz, down to -50dB

- FFTA-12 (Thickness: 12″) for K-band frequency absorption at 500MHz, down to -50dB

- FFTA-18 (Thickness: 18″) for K-band frequency absorption at 350MHz, down to -50dB

- FFTA-24 (Thickness: 24″) for K-band frequency absorption at 250MHz, down to -50dB

- FFTA-36 (Thickness: 36″) for K-band frequency absorption at 250MHz, down to -50dB

- FFTA-48 (Thickness: 48″) for K-band frequency absorption at 250MHz, down to -50dB

- FFTA-50 (Thickness: 50″) for K-band frequency absorption at 250MHz, down to -50dB

What’s the next step in integrating EMI and Microwave absorbers into your project?

We’re happy to help you choose the right EMI absorbers for your project.

Send us a message using the contact form or chat. We’ll get back to you as soon as possible!