Custom heat sinks

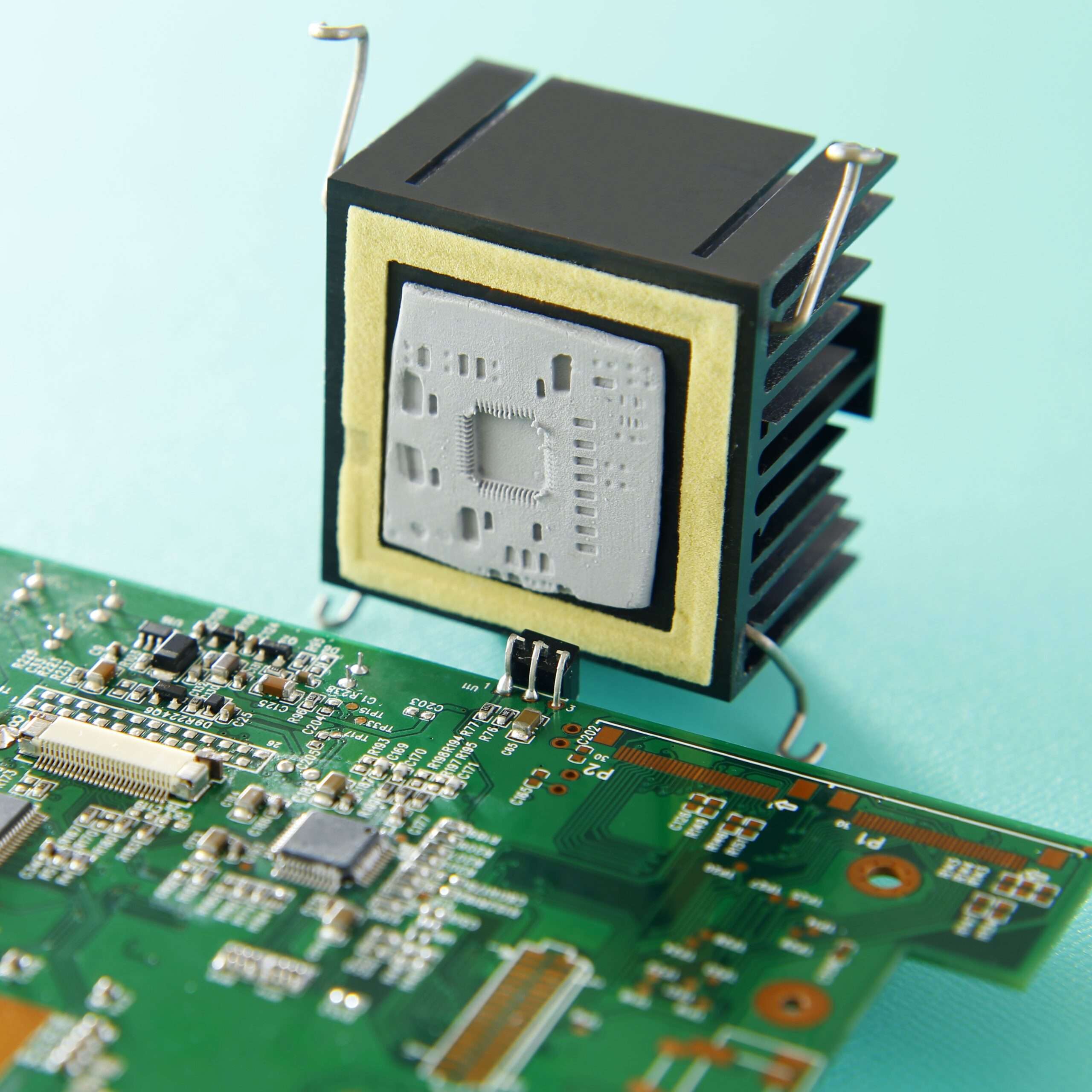

Heat sinks dissipate heat from electronic components and assemblies

Custom heat sinks are metal parts (mainly aluminium, might be copper) with the largest possible contact surfaces with exterior air. The aim is to dissipate heat by convection, radiation and conduction.

Heat transfer can be increased by adding fans mounted on the heatsink, thermal interfaces between the heatsink and the components, etc.

The profiles used for the heatsinks can be standard (see catalogue) or custom made. In all cases, machining and specific surface treatments are possible.

Custom heat sinks, Key points :

- Standard materials are aluminium or copper (for higher performances).

- Extrusion of standard or customised profiles or forging

- CNC machining for prototypes

- Surface treatment on request (Surtec 650, Anodising)

- Production on drawing for custom heat sinks

Large catalogue of standard heat sinks profiles available and customised profiles possible (dimensions, materials, assemblies, etc).

Prototypes and samples on request.

Description of custom heat sinks for thermal management

Heat sinks are mechanical parts with standard or specific profiles used to dissipate heat from electronic components of all sizes (PCBs, CPUs, GPUs).

They dissipate heat by conduction, radiation and convection.

About heat sinks :

Using a standard extrusion profile for your heat sink is a good alternative between custom-made and off-the-shelf heat sinks. The custom heat sink is extruded from the profile. We then machine the part again to adapt it to the drawing, add the holes, cut off the excess, etc. Once the heat sink has been machined, we can add a bath surface treatment (Surtec 650 or anodising).

Bear in mind that the Surtec 650 surface treatment protects the heatsink while maintaining electrical conductivity. Anodising is an electrical insulator.

We can supply your custom heat sinks raw or assembled with a suitable thermal interface. We can also supply these thermal interfaces separately. Using a thermal interface ensures complete mechanical contact between the heat sink and the component (by eliminating the air, which is a thermal insulator). For more information, see our article on choosing a thermal interface material.

If you can’t find the right profile for your application, we can produce tooling to drawing. We can also help you with the thermal simulation of your equipment and the definition of the appropriate heatsink profile.

Compelma supplies custom heat sinks from prototypes to series production.

For further information or advice, our team is available to answer your questions.

Catalogue of Standard Profiles for Custom Heat Sinks

Re-machining and surface treatment on request

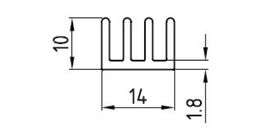

Heatsink – Profile AD

Width : 14 mm

Height : 10 mm

Nb fins : 4

Rth (°C/W) : 54,2

Length : 50 mm

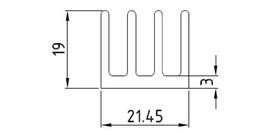

Heatsink – Profile AE

Width : 21,45 mm

Height : 19 mm

Nb fins : 4

Rth (°C/W) : 28,7

Length : 50 mm

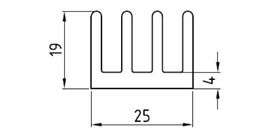

Heatsink – Profile AT

Width : 25 mm

Height : 19 mm

Nb fins : 4

Rth (°C/W) : 28,7

Length : 50 mm

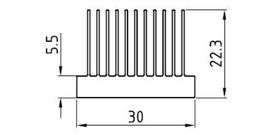

Heatsink – Profile AO

Width : 30 mm

Height : 22,3 mm

Nb fins : 10

Rth (°C/W) : 11,8

Length : 50 mm

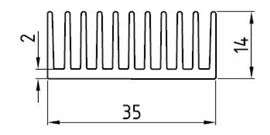

Heatsink – Profile AR

Width : 35 mm

Height : 14 mm

Nb fins : 11

Rth (°C/W) : 14,9

Length : 50 mm

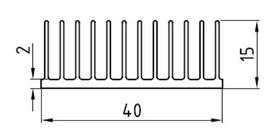

Heatsink – Profile BF

Width : 40 mm

Height : 15 mm

Nb fins : 12

Rth (°C/W) : 12,7

Length : 50 mm

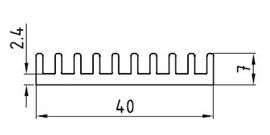

Heatsink – Profile BE

Width: 40 mm

Height : 7 mm

Nb d’ailettes : 10

Rth (°C/W) : 32,2

Length : 50 mm

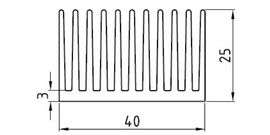

Heatsink – Profile BG

Width : 40 mm

Height : 25 mm

Nb fins : 11

Rth (°C/W) : 8,5

Length : 50 mm

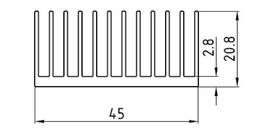

Heatsink – Profile BR

Width : 45 mm

Height : 20,8 mm

Nb fins : 12

Rth (°C/W) : 9,3

Length : 50 mm

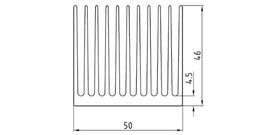

Heatsink – Profile BX

Width : 50 mm

Height : 46 mm

Nb fins : 11

Rth (°C/W) : 4,7

Length : 50 mm

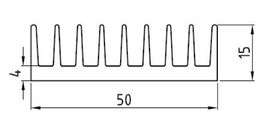

Heatsink – Profile BY

Width : 50 mm

Height : 15 mm

Nb fins : 9

Rth (°C/W) : 17

Length : 50 mm

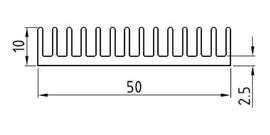

Heatsink – Profile CJ

Width : 50 mm

Height : 10 mm

Nb fins : 11

Rth (°C/W) : 16,8

Length : 50 mm

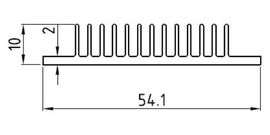

Heatsink – Profile CI

Width : 54,1 mm

Height : 10 mm

Nb fins : 13

Rth (°C/W) : 16,8

Length : 50 mm

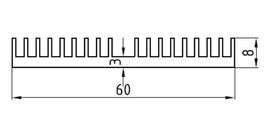

Heatsink – Profile DB

Width : 60 mm

Height : 8 mm

Nb fins : 18

Rth (°C/W) : 17,8

Length : 50 mm

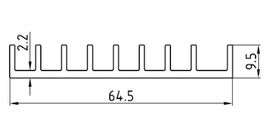

Heatsink – Profile DQ

Width : 64,5 mm

Height : 9,5 mm

Nb fins : 9

Rth (°C/W) : 22

Length : 50 mm

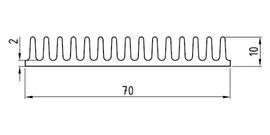

Heatsink – Profile EA

Width : 70 mm

Height : 10 mm

Nb fins : 16

Rth (°C/W) : 13,6

Length : 50 mm

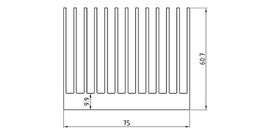

Heatsink – Profile EO

Width : 75 mm

Height : 60,7 mm

Nb fins : 13

Rth (°C/W) : 3,1

Length : 50 mm

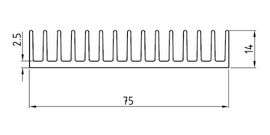

Heatsink – Profile EP

Width : 75 mm

Height : 14 mm

Nb fins : 15

Rth (°C/W) : 10,5

Length : 50 mm

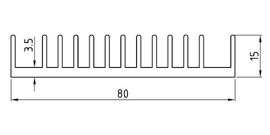

Heatsink – Profile EY

Width : 80 mm

Height : 15 mm

Nb fins : 13

Rth (°C/W) : 11,3

Length : 50 mm

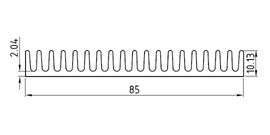

Heatsink – Profile FU

Width : 85mm

Height : 10,13 mm

Nb fins : 20

Rth (°C/W) : 10,9

Length : 50 mm

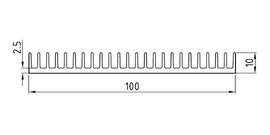

Heatsink – Profile GS

Width : 100 mm

Height : 10 mm

Nb fins : 24

Rth (°C/W) : 9,6

Length : 50 mm

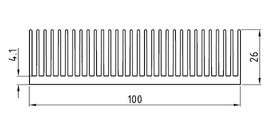

Heatsink – Profile GU

Width : 100 mm

Height : 26 mm

Nb fins : 31

Rth (°C/W) : 3,1

Length : 50 mm

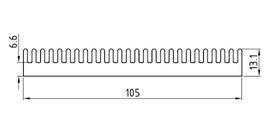

Heatsink – Profile HK

Width : 105 mm

Height : 13,1 mm

Nb fins : 28

Rth (°C/W) : 8,6

Length : 50 mm

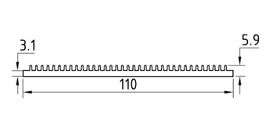

Heatsink – Profile HT

Width : 110mm

Height : 5,9 mm

Nb fins : 36

Rth (°C/W) : 13,5

Length : 50 mm

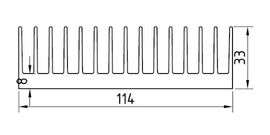

Heatsink – Profile HV

Width : 114 mm

Height : 33 mm

Nb fins : 15

Rth (°C/W) : 4,8

Length : 50 mm

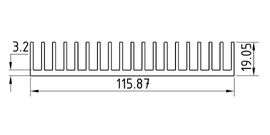

Heatsink – Profile IG

Width : 115,87 mm

Height : 19,05 mm

Nb fins : 19

Rth (°C/W) : 6,1

Length : 50 mm

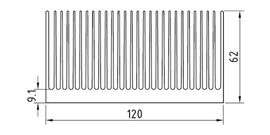

Heatsink – Profile IK

Width : 120 mm

Height : 62 mm

Nb fins : 28

Rth (°C/W) : 1,5

Length : 50 mm

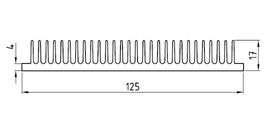

Heatsink – Profile IS

Width : 125 mm

Height : 17 mm

Nb fins : 29

Rth (°C/W) : 13,5

Length : 50 mm

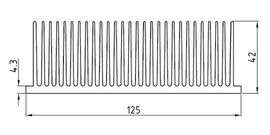

Heatsink – Profile IT

Width : 125 mm

Height : 42 mm

Nb fins : 29

Rth (°C/W) : 2

Length : 50 mm

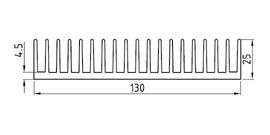

Heatsink – Profile ID

Width : 130 mm

Height : 25 mm

Nb fins : 19

Rth (°C/W) : 4,8

Length : 50 mm

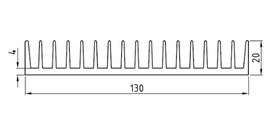

Heatsink – Profile IU

Width : 130 mm

Height : 20 mm

Nb fins : 18

Rth (°C/W) : 6,1

Length : 50 mm

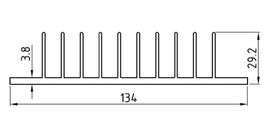

Heatsink – Profile JA

Width : 134 mm

Height : 29,2 mm

Nb fins : 10

Rth (°C/W) : 6,7

Length : 50 mm

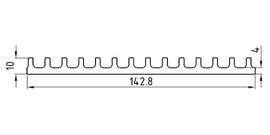

Heatsink – Profile JD

Width : 142,8 mm

Height : 10 mm

Nb fins : 14

Rth (°C/W) : 12,8

Length : 50 mm

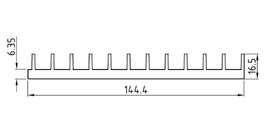

Heatsink – Profile JF

Width : 144,4 mm

Height : 16,5 mm

Nb fins : 12

Rth (°C/W) : 9,7

Length : 50 mm

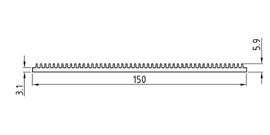

Heatsink – Profile JK

Width : 150 mm

Height : 5,9 mm

Nb fins : 50

Rth (°C/W) : 9,8

Length : 50 mm

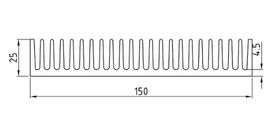

Heatsink – Profile JM

Width : 150 mm

Height : 25 mm

Nb fins : 24

Rth (°C/W) : 3,9

Length : 50 mm

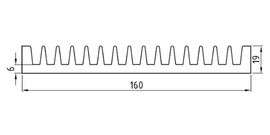

Heatsink – Profile JT

Width : 160 mm

Height : 19 mm

Nb fins : 14

Rth (°C/W) : 7,1

Length : 50 mm

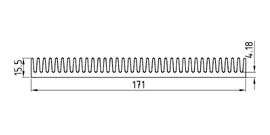

Heatsink – Profile KJ

Width : 171 mm

Height : 15,5 mm

Nb fins : 36

Rth (°C/W) : 4,4

Length : 50 mm

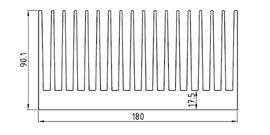

Heatsink – Profile KP

Width : 180 mm

Height : 90,1 mm

Nb fins : 18

Rth (°C/W) : 1,5

Length : 50 mm

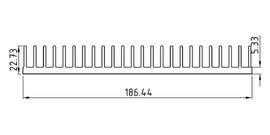

Heatsink – Profile KS

Width : 186,44 mm

Height : 22,73 mm

Nb fins : 25

Rth (°C/W) : 4

Length : 50 mm

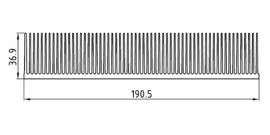

Heatsink – Profile KT

Width : 190,5 mm

Height : 26,9 mm

Nb fins : 62

Rth (°C/W) : 1,4

Length : 50 mm

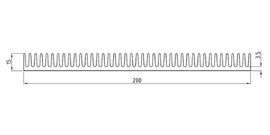

Heatsink – Profile KZ

Width : 200 mm

Height : 15 mm

Nb fins : 41

Rth (°C/W) : 3,7

Length : 50 mm

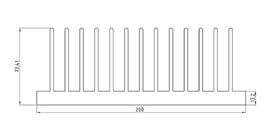

Heatsink – Profile LD

Width : 200 mm

Height : 73,41 mm

Nb fins : 13

Rth (°C/W) : 2,3

Length : 50 mm

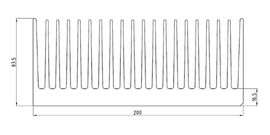

Heatsink – Profile LE

Width : 200 mm

Height : 83,5 mm

Nb fins : 20

Rth (°C/W) : 0,8

Length : 50 mm

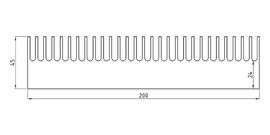

Heatsink – Profile LB

Width : 200 mm

Height : 45 mm

Nb fins : 30

Rth (°C/W) : 2,4

Length : 50 mm

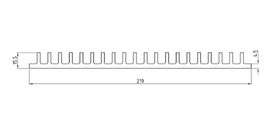

Heatsink – Profile LI

Width : 219 mm

Height : 15,5 mm

Nb fins : 20

Rth (°C/W) : 6,2

Length : 50 mm

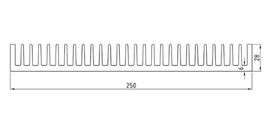

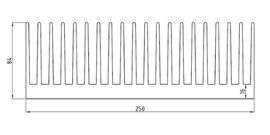

Heatsink – Profile LT

Width : 250 mm

Height : 28 mm

Nb fins : 28

Rth (°C/W) : 2,9

Length : 50 mm

Heatsink – Profile LU

Width : 250 mm

Height : 84 mm

Nb fins : 20

Rth (°C/W) : 1,4

Length : 50 mm

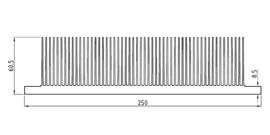

Heatsink – Profile LV

Width : 250 mm

Height : 60,5 mm

Nb fins : 56

Rth (°C/W) : 0,8

Length : 50 mm

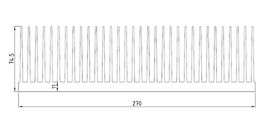

Heatsink – Profile MB

Width : 270 mm

Height : 74,5 mm

Nb fins : 32

Rth (°C/W) : 1

Length : 50 mm

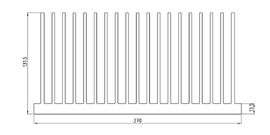

Heatsink – Profile MC

Width : 270 mm

Height : 131,5 mm

Nb fins : 20

Rth (°C/W) : 0,9

Length : 50 mm

Heatsink – Profile LX

Width : 300 mm

Height : 41,5 mm

Nb fins : 32

Rth (°C/W) : 1,8

Length : 50 mm

Heatsink – Profile MG

Width : 300 mm

Height : 84,2 mm

Nb fins : 23

Rth (°C/W) : 1,2

Length : 50 mm

Heatsink – Profile MJ

Width : 360 mm

Height : 90,5 mm

Nb fins : 48

Rth (°C/W) : 0,6

Length : 50 mm