EMI Shielding Silicone Gaskets

Conductive and standard silicone EMI gaskets provide wave (EM and RF) and fluid (IP) sealing

EMI shielding gaskets in conductive silicone (loaded with conductive particles) provide EMI shielding and resistance to the external environment (IP sealing) with one unique gasket.

These EMI silicone gaskets are extruded in length (standard or custom profiles). Then delivered in coils or joined to length. They can also be molded or cut to size (for flat joints, connector shielding type).

These EMI gaskets can be made of pure silicone (60 Shore A) or bi-material (hardness 40 Shore A).

We support you on the type of load and EMI gasket profile according to the specifications to be achieved and the environmental constraints.

EMI shielding silicone gaskets, key points:

- One EMI silicone gasket make EMI sealing and IP sealing (thanks to the compression)

- Mechanical strength and conductivity guaranteed over time (by the stability of the silicone)

- Standard and custom profiles of EMI shielding silicone gasket for extrusion

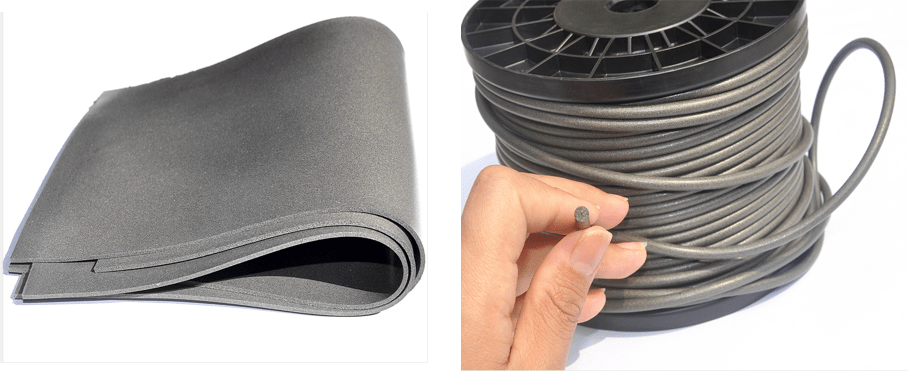

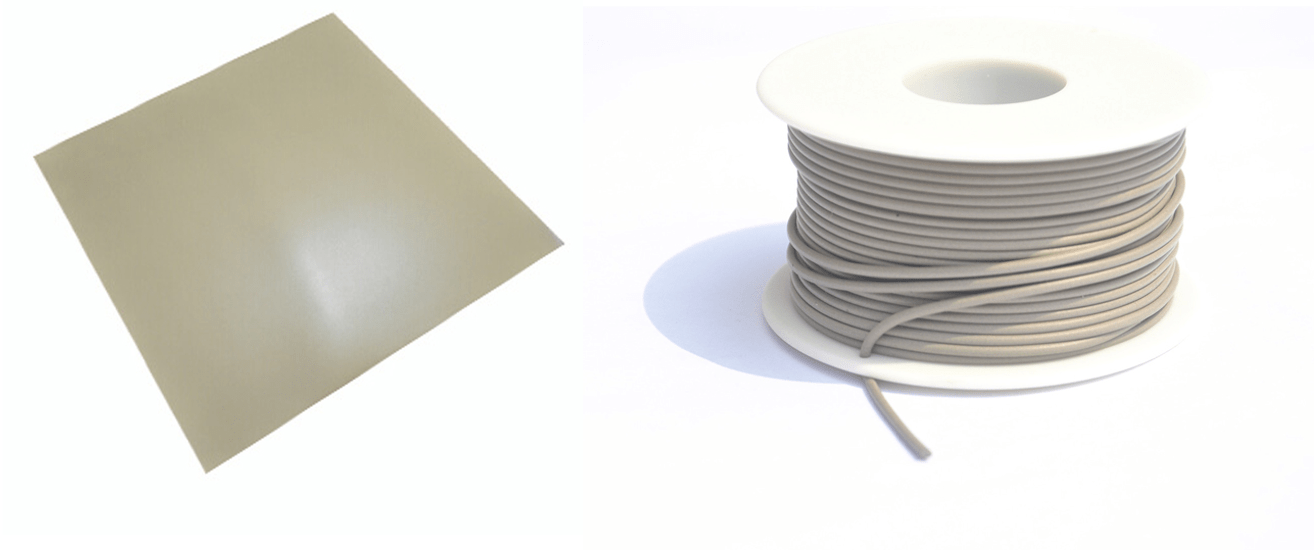

- Cutting EMI shielding silicone sheets for flat seals

- Conductive fluoro-silicone available for better resistance to solvents and hydrocarbons

- Several types of fillers (Ni/C, Ag/Al, Cu/Ag) to be used on EMI shielding conductive gaskets.

Large catalog of standard EMI shielding conductive gaskets available and custom-made parts possible (dimensions, thickness, materials, overmolding, etc.).

Support on the sizing of the EMI gaskets and on integration (type of profile, groove, tightening, etc.)

Prototypes and samples of EMI shielding conductive gaskets on request.

EMI sealing gaskets with conductive silicone

EMI shielding gaskets with conductive silicone are extruded using a standard or a specific profile, or cut from a flat sheet of conductive silicone.

The silicone material is mixed with metallic particles (therefore conductive) to ensure electrical conductivity throughout the material. The particles used are (mainly) nickel and graphite or silver and aluminum.

This conductive silicone is then extruded or molded to make electromagnetic (EM) and radio frequency (RF) shielding seals.

Extrusion can also be done simultaneously with two silicones. A charged silicone (conductive but harder) and a neutral silicone (softer and non conductive). We thus obtain bi-material seals with more interesting mechanical behavior than pure filled silicone (better flexibility and therefore better IP sealing level).

Learn more about EMI shielding silicone gaskets and conductive particles used

These EMI shielding silicone gaskets provide excellent electromagnetic and fluid tightness (up to IP68 see IP69)

Due to their high resistance, these conductive joints are widely used on military, telecoms, medical or nuclear projects.

EMI silicone gaskets for EMC and/or IP can be manufactured by extrusion following a standard or custom profile. Extruded silicone shielding gaskets can be delivered by linear meter or supplied joined to a specific length.

How to choose an EMC shielding gasket? See our article on CEM/EMI shielding seals.

Kind of conductive silicone used for the manufacturing of EMI shielding conductive gaskets.

Loaded Silicone with Carbone and Nickel particles (Ni/C)

Conductive silicone with silver and aluminium conductive particles (Ag/Al)

Comparaison between Ni/C and Ag/Al conductive silicone :

Color:

- Ni/C : Dark grey

- Ag/Al : White/Grey

Volume resistivity:

- Ni/C : 0.1 Ω*cm

- Ag/Al :<0.008 Ω*cm

Density:

- Ni/C : 2.0 to 2.3 g/cm³ ±0.1

- Ag/Al : 2.1 g/cm³ ±0.05

Hardness:

- Ni/C : 55 to 75 Shore A ±5

- Ag/Al : 65 to 78 Shore A ±5

Tensile strenght:

- Ni/C : 1.4 to 2 MPa

- Ag/Al : 1.5 to 2MPa

Elongation at break:

- Ni/C : 60 (fluorosilicone) to 100%

- Ag/Al : 30 (fluorosilicone) to 50%

Tear strength:

- Ni/C : 4.0 to 6.2 kN/m

- Ag/Al : 5.3 kN/m

Compression set:

- Ni/C : 25 to 30%

- Ag/Al : 30%

Temperature range:

- Ni/C : -45°C to +150°C

- Ag/Al : -55 to 160°C

EMI/EMC Shielding effectiveness (from 100MHz to 18GHz):

- Ni/C : 95dB to 115dB

- Ag/Al : 100dB to 115dB

Flame retardant (UL94 certification):

- Ni/C : HB to V-0

- Ag/Al : HB to V-0

Reach and RoHS certification:

- Ni/C : Certified

- Ag/Al : Certified

A project, a request ?

Catalogue of EMI silicone shielding gasket (Ni/C or Ag/Al)

Standard profils of EMI shielding silicone gaskets, extruded or molded

This catalog lists the different main standard existing profiles.

If you don’t find what you are looking for, please contact us.

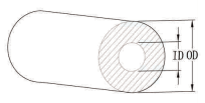

EMI shielding silicone gaskets with extruded conductive silicone : O Type

References/Dimensions

| Dimensions | ID (mm) | OD (mm) |

| BH-E 0000XE-H01023Y | 1.02 | 0.33 |

| BH-E 0000XE-H01025Y | 1.02 | 0.51 |

| BH-E 0000XE-H01206Y | 1.20 | 0.60 |

| BH-E 0000XE-H01205Y | 1.20 | 0.55 |

| BH-E 0000XE-H01355Y | 1.35 | 0.51 |

| BH-E 0000XE-H01403Y | 1.40 | 0.30 |

| BH-E 0000XE-H01456Y | 1.45 | 0.60 |

| BH-E 0000XE-H01506Y | 1.50 | 0.60 |

| BH-E 0000XE-H01575Y | 1.57 | 0.51 |

| BH-E 0000XE-H01576Y | 1.57 | 0.60 |

| BH-E 0000XE-H01577Y | 1.57 | 0.76 |

| BH-E 0000XE-H01578Y | 1.57 | 0.89 |

| BH-E 0000XE-H01657Y | 1.65 | 0.76 |

| BH-E 0000XE-H01785Y | 1.78 | 0.51 |

| BH-E 0000XE-H01786Y | 1.78 | 0.64 |

| BH-E 0000XE-H01787Y | 1.78 | 0.76 |

| BH-E 0000XE-H01780Y | 1.78 | 1.02 |

| BH-E 0000XE-H01880Y | 1.88 | 1.02 |

| BH-E 0000XE-H02005Y | 2.00 | 1.00 |

| BH-E 0000XE-H02025Y | 2.00 | 0.51 |

| BH-E 0000XE-H02037Y | 2.03 | 0.76 |

| BH-E 0000XE-H02030Y | 2.03 | 1.02 |

| BH-E 0000XE-H02080Y | 2.08 | 1.02 |

| BH-E 0000XE-H02100Y | 2.10 | 1.02 |

| BH-E 0000XE-H02150Y | 2.15 | 1.02 |

| BH-E 0000XE-H02200Y | 2.20 | 1.00 |

| BH-E 0000XE-H02205Y | 2.20 | 1.50 |

| BH-E 0000XE-H02303Y | 2.30 | 1.30 |

| BH-E 0000XE-H02337Y | 2.33 | 0.76 |

| BH-E 0000XE-H02352Y | 2.33 | 1.27 |

| BH-E 0000XE-H02360Y | 2.36 | 1.02 |

| BH-E 0000XE-H02418Y | 2.40 | 1.80 |

| BH-E 0000XE-H02480Y | 2.40 | 0.80 |

| BH-E 0000XE-H02508Y | 2.50 | 0.80 |

| BH-E 0000XE-H02547Y | 2.54 | 1.78 |

| BH-E 0000XE-H02623Y | 2.62 | 1.35 |

| BH-E 0000XE-H02624Y | 2.62 | 1.40 |

| BH-E 0000XE-H02625Y | 2.62 | 1.52 |

| BH-E 0000XE-H02686Y | 2.68 | 1.62 |

| BH-E 0000XE-H02805Y | 2.80 | 1.80 |

| BH-E 0000XE-H02840Y | 2.84 | 1.02 |

| BH-E 0000XE-H03001Y | 3.00 | 1.14 |

| BH-E 0000XE-H03005Y | 3.00 | 2.00 |

| BH-E 0000XE-H03002Y | 3.00 | 2.00 |

| BH-E 0000XE-H03100Y | 3.10 | 1.00 |

| BH-E 0000XE-H03181Y | 3.18 | 1.14 |

| BH-E 0000XE-H03210Y | 3.20 | 1.10 |

| BH-E 0000XE-H03210Y | 3.20 | 1.10 |

| BH-E 0000XE-H03206Y | 3.20 | 1.60 |

| BH-E 0000XE-H03230Y | 3.30 | 2.10 |

| BH-E 0000XE-H03401Y | 3.40 | 1.14 |

| BH-E 0000XE-H03558Y | 3.55 | 1.80 |

| BH-E 0000XE-H03703Y | 3.70 | 2.00 |

| BH-E 0000XE-H04003Y | 4.00 | 2.00 |

| BH-E 0000XE-H04002Y | 4.00 | 2.00 |

| BH-E 0000XE-H04005Y | 4.00 | 2.50 |

| BH-E 0000XE-H04080Y | 4.00 | 2.82 |

| BH-E 0000XE-H04485Y | 4.48 | 2.50 |

| BH-E 0000XE-H04830Y | 4.83 | 2.03 |

| BH-E 0000XE-H05002Y | 5.00 | 2.50 |

| BH-E 0000XE-H05253Y | 5.25 | 3.00 |

| BH-E 0000XE-H05333Y | 5.33 | 2.36 |

| BH-E 0000XE-H05606Y | 5.60 | 2.60 |

| BH-E 0000XE-H05803Y | 5.80 | 3.00 |

| BH-E 0000XE-H06009Y | 6.00 | 1.90 |

| BH-E 0000XE-H06004Y | 6.00 | 4.00 |

| BH-E 0000XE-H06401Y | 6.40 | 3.15 |

| BH-E 0000XE-H06402Y | 6.45 | 3.18 |

| BH-E 0000XE-H06802Y | 6.80 | 5.20 |

| BH-E 0000XE-H07080Y | 7.00 | 2.80 |

| BH-E 0000XE-H07004Y | 7.00 | 4.00 |

| BH-E 0000XE-H07007Y | 7.00 | 4.70 |

| BH-E 0000XE-H07005Y | 7.00 | 5.00 |

| BH-E 0000XE-H07006Y | 7.00 | 6.00 |

| BH-E 0000XE-H07805Y | 7.80 | 4.50 |

| BH-E 0000XE-H07929Y | 7.92 | 2.92 |

| BH-E 0000XE-H08040Y | 8.00 | 5.40 |

| BH-E 0000XE-H08265Y | 8.26 | 5.00 |

| BH-E 0000XE-H10006Y | 10.00 | 10.00 |

| BH-E 0000XE-H12800Y | 12.80 | 10.00 |

| BH-E 0000XE-H13209Y | 13.20 | 7.95 |

Custom profiles on demand

Possible profiles:

Ext. diam. between Ø0.8 and 13mm

Int. Diam. ≥ Ø0.33mm

Thickness ≥ 0.3mm

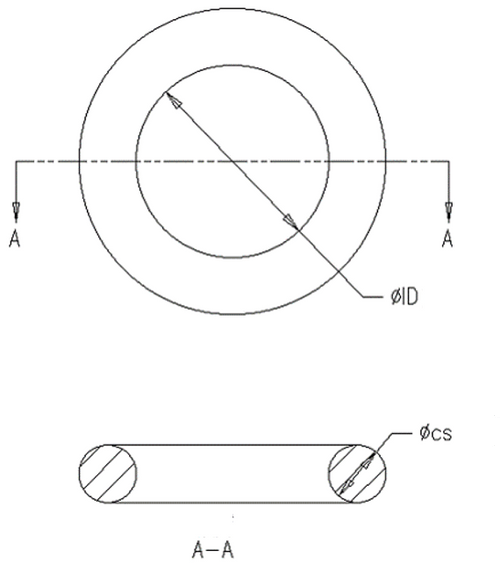

EMI shielding silicone gaskets with extruded conductive silicone : O Ring Type

References/Dimensions

| Dimensions | ID (mm) | CS (mm) |

| CMOR-1 | 1,25 | 0,40 |

| CMOR-2 | 2,75 | 0,75 |

| CMOR-3 | 2,80 | 0,80 |

| CMOR-4 | 3,5 | 1 |

| CMOR-5 | 4 | 1 |

| CMOR-6 | 4,40 | 1 |

| CMOR-7 | 6 | 1,5 |

| CMOR-8 | 6 | 1 |

| CMOR-9 | 6,5 | 1,8 |

| CMOR-10 | 8 | 1 |

| CMOR-12 | 9 | 1,3 |

| CMOR-11 | 9 | 1,5 |

| CMOR-15 | 10 | 1,2 |

| CMOR-17 | 10 | 1,8 |

| CMOR-14 | 10 | 1,5 |

| CMOR-18 | 10 | 1,3 |

| CMOR-16 | 10 | 1,6 |

| CMOR-19 | 10 | 1 |

| CMOR-13 | 10 | 1 |

| CMOR-20 | 11,8 | 1,8 |

| CMOR-24 | 14 | 1,2 |

| CMOR-22 | 14 | 1,2 |

| CMOR-21 | 14 | 1,8 |

| CMOR-23 | 14 | 1,5 |

| CMOR-25 | 15,49 | 1,78 |

| CMOR-26 | 15,50 | 2 |

| CMOR-28 | 16 | 2,65 |

| CMOR-27 | 16 | 1 |

| CMOR-29 | 16,8 | 2 |

| CMOR-30 | 17,5 | 1,8 |

| CMOR-32 | 18 | 1 |

| CMOR-33 | 18 | 2,65 |

| CMOR-31 | 18 | 1,8 |

| CMOR-34 | 18 | 2,65 |

| CMOR-35 | 18,54 | 1,78 |

| CMOR-36 | 22,40 | 2,65 |

| CMOR-37 | 23 | 2 |

| CMOR-38 | 24,80 | 2 |

| CMOR-39 | 25 | 2,65 |

| CMOR-40 | 25,12 | 2 |

| CMOR-41 | 25,50 | 2,65 |

| CMOR-42 | 26 | 2,65 |

| CMOR-43 | 28 | 4,50 |

| CMOR-44 | 31,50 | 2 |

| CMOR-45 | 31,80 | 2,65 |

| CMOR-46 | 32 | 2,65 |

| CMOR-47 | 36,50 | 2,65 |

| CMOR-48 | 45 | 4 |

| CMOR-49 | 54,05 | 4,80 |

Custom profiles on demand.

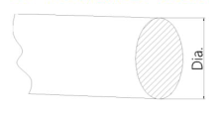

EMI shielding silicone gaskets with extruded conductive silicone : Solid O Shape

References/Dimensions

| Référence | DIA (mm) |

| BH-E 0000XE-S0060Y | 0,6 |

| BH-E 0000XE-S0081Y | 0,81 |

| BH-E 0000XE-S0090Y | 0,9 |

| BH-E 0000XE-S0102Y | 1,02 |

| BH-E 0000XE-S0110Y | 1,1 |

| BH-E 0000XE-S0120Y | 1,2 |

| BH-E 0000XE-S0128Y | 1,28 |

| BH-E 0000XE-S0135Y | 1,35 |

| BH-E 0000XE-S0140Y | 1,4 |

| BH-E 0000XE-S0153Y | 1,53 |

| BH-E 0000XE-S0157Y | 1,57 |

| BH-E 0000XE-S0165Y | 1,65 |

| BH-E 0000XE-S0178Y | 1,78 |

| BH-E 0000XE-S0184Y | 1,84 |

| BH-E 0000XE-S0190Y | 1,9 |

| BH-E 0000XE-S0203Y | 2,03 |

| BH-E 0000XE-S0208Y | 2,08 |

| BH-E 0000XE-S0210Y | 2,1 |

| BH-E 0000XE-S0220Y | 2,2 |

| BH-E 0000XE-S0230Y | 2,3 |

| BH-E 0000XE-S0236Y | 2,36 |

| BH-E 0000XE-S0240Y | 2,4 |

| BH-E 0000XE-S0254Y | 2,54 |

| BH-E 0000XE-S0262Y | 2,62 |

| BH-E 0000XE-S0268Y | 2,68 |

| BH-E 0000XE-S0284Y | 2,84 |

| BH-E 0000XE-S0302Y | 3,02 |

| BH-E 0000XE-S0318Y | 3,18 |

| BH-E 0000XE-S0320Y | 3,2 |

| BH-E 0000XE-S0330Y | 3,3 |

| BH-E 0000XE-S0340Y | 3,4 |

| BH-E 0000XE-S0353Y | 3,53 |

| BH-E 0000XE-S0370Y | 3,7 |

| BH-E 0000XE-S0381Y | 3,81 |

| BH-E 0000XE-S0396Y | 3,96 |

| BH-E 0000XE-S0405Y | 4,05 |

| BH-E 0000XE-S0425Y | 4,25 |

| BH-E 0000XE-S0430Y | 4,3 |

| BH-E 0000XE-S0448Y | 4,48 |

| BH-E 0000XE-S0478Y | 4,78 |

| BH-E 0000XE-S0500Y | 5 |

| BH-E 0000XE-S0508Y | 5,08 |

| BH-E 0000XE-S0525Y | 5,25 |

| BRL-E 000XE-S0533Y | 5,33 |

| BRL-E 000XE-S0540Y | 5,4 |

| BRL-E 000XE-S0549Y | 5,49 |

| BRL-E 000XE-S0560Y | 5,6 |

| BRL-E 000XE-S0600Y | 6 |

| BRL-E 000XE-S0640Y | 6,4 |

| BRL-E 000XE-S0660Y | 6,6 |

| BRL-E 000XE-S0680Y | 6,8 |

| BRL-E 000XE-S0700Y | 7 |

| BRL-E 000XE-S0780Y | 7,8 |

| BRL-E 000XE-S0792Y | 7,92 |

| BRL-E 000XE-S0800Y | 8 |

| BRL-E 000XE-S0826Y | 8,26 |

| BRL-E 000XE-S1000Y | 10 |

| BRL-E 000XE-S1280Y | 12,8 |

| BRL-E 000XE-S1320Y | 13,2 |

| BRL-E 000XE-S1350Y | 13,5 |

| BRL-E 000XE-S1500Y | 15 |

Custom profiles on demand

Between Ø0.6 and 13mm

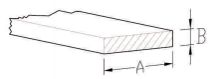

EMI shielding silicone gaskets with extruded conductive silicone : Rectangular shape

References/Dimensions

| Dimensions | A (mm) | B (mm) |

| BH-E 0000XE-R0099Y | 0.90 | 0.90 |

| BH-E 0000XE-R0108Y | 1.00 | 0.90 |

| BH-E 0000XE-R0144Y | 1.49 | 1.48 |

| BH-E 0000XE-R0160Y | 1.60 | 1.07 |

| BH-E 0000XE-R0205Y | 2.00 | 1.50 |

| BH-E 0000XE-R0203Y | 2.00 | 1.30 |

| BH-E 0000XE-R0202Y | 2.00 | 2.00 |

| BH-E 0000XE-R0201Y | 2.00 | 2.00 |

| BH-E 0000XE-R0241Y | 2.40 | 1.25 |

| BH-E 0000XE-R0246Y | 2.45 | 1.45 |

| BH-E 0000XE-R0259Y | 2.59 | 0.98 |

| BH-E 0000XE-R0299Y | 3.00 | 1.00 |

| BH-E 0000XE-R0307Y | 3.00 | 0.98 |

| BH-E 0000XE-R0301Y | 3.00 | 1.50 |

| BH-E 0000XE-R0305Y | 3.00 | 2.00 |

| BH-E 0000XE-R0312Y | 3.10 | 2.00 |

| BH-E 0000XE-R0310Y | 3.18 | 1.02 |

| BH-E 0000XE-R0315Y | 3.18 | 1.57 |

| BH-E 0000XE-R0314Y | 3.18 | 2.40 |

| BH-E 0000XE-R0303Y | 3.20 | 1.50 |

| BH-E 0000XE-R0327Y | 3.20 | 2.70 |

| BH-E 0000XE-R0320Y | 3.24 | 1.03 |

| BH-E 0000XE-R0309Y | 3.50 | 1.90 |

| BH-E 0000XE-R0374Y | 3.70 | 1.40 |

| BH-E 0000XE-R0401Y | 4.00 | 1.00 |

| BH-E 0000XE-R0408Y | 4.00 | 0.80 |

| BH-E 0000XE-R0406Y | 4.00 | 1.60 |

| BH-E 0000XE-R0421Y | 4.25 | 2.15 |

| BH-E 0000XE-R0451Y | 4.50 | 1.00 |

| BH-E 0000XE-R0455Y | 4.50 | 2.50 |

| BH-E 0000XE-R0459Y | 4.52 | 1.91 |

| BH-E 0000XE-R0482Y | 4.80 | 3.20 |

| BH-E 0000XE-R0508Y | 5.00 | 0.80 |

| BH-E 0000XE-R0507Y | 5.00 | 2.75 |

| BH-E 0000XE-R0500Y | 5.00 | 2.00 |

| BH-E 0000XE-R0523Y | 5.20 | 3.50 |

| BH-E 0000XE-R0535Y | 5.35 | 1.57 |

| BH-E 0000XE-R0550Y | 5.50 | 1.02 |

| BH-E 0000XE-R0601Y | 6.00 | 1.00 |

| BH-E 0000XE-R0635Y | 6.35 | 0.51 |

| BH-E 0000XE-R0638Y | 6.35 | 0.81 |

| BH-E 0000XE-R0636Y | 6.35 | 1.57 |

| BH-E 0000XE-R0633Y | 6.35 | 2.36 |

| BH-E 0000XE-R0801Y | 8.00 | 1.00 |

| BH-E 0000XE-R0850Y | 8.50 | 1.00 |

| BH-E 0000XE-R0915Y | 9.15 | 1.57 |

| BH-E 0000XE-R0950Y | 9.50 | 1.00 |

| BH-E 0000XE-R0958Y | 9.53 | 0.81 |

| BH-E 0000XE-R1008Y | 10.00 | 1.07 |

| BH-E 0000XE-R1001Y | 10.00 | 2.00 |

| BH-E 0000XE-R1080Y | 10.00 | 8.00 |

| BH-E 0000XE-R1028Y | 10.25 | 0.80 |

| BH-E 0000XE-R1104Y | 11.00 | 0.40 |

| BH-E 0000XE-R1208Y | 12.00 | 0.80 |

| BH-E 0000XE-R1205Y | 12.70 | 0.51 |

| BH-E 0000XE-R1272Y | 12.70 | 1.20 |

| BH-E 0000XE-R1275Y | 12.70 | 1.57 |

| BH-E 0000XE-R1279Y | 12.70 | 1.91 |

| BH-E 0000XE-R1271Y | 12.70 | 3.18 |

| BH-E 0000XE-R1277Y | 12.70 | 4.78 |

| BH-E 0000XE-R1273Y | 12.70 | 6.35 |

| BH-E 0000XE-R1300Y | 13.00 | 1.08 |

| BH-E 0000XE-R1501Y | 15.00 | 1.00 |

| BH-E 0000XE-R1573Y | 15.75 | 3.18 |

| BH-E 0000XE-R2005Y | 20.00 | 1.50 |

| BH-E 0000XE-R2605Y | 26.00 | 1.57 |

| BH-E 0000XE-R2615Y | 26.10 | 1.57 |

| BH-E 0000XE-R2645Y | 26.40 | 1.57 |

| BH-E 0000XE-R2975Y | 29.70 | 1.57 |

| BH-E 0000XE-R3005Y | 30.00 | 1.57 |

| BH-E 0000XE-R3003Y | 30.00 | 3.00 |

| BH-E 0000XE-R4003Y | 40.00 | 3.00 |

Custom profile on demand

Possible profiles:

Width ≥0.8mm

Height ≥0.4mm

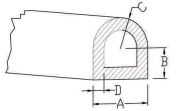

EMI shielding silicone gaskets with extruded conductive silicone : D Type

References/Dimensions

| Référence | A (mm) | B (mm) | D (mm) | C (mm) |

| BH-E 0000XE-D2101Y | 1.45 | 0.90 | 0.40 | 0.72 |

| BH-E 0000XE-D2102Y | 2.00 | 1.00 | 0.50 | 1.00 |

| BH-E 0000XE-D2103Y | 2.00 | 1.30 | 0.50 | 1.00 |

| BH-E 0000XE-D2145Y | 2.16 | 1.30 | 0.80 | 1.08 |

| BH-E 0000XE-D2140Y | 2.77 | 1.78 | 0.60 | 1.39 |

| BH-E 0000XE-D2105Y | 3.00 | 2.46 | 0.70 | 1.50 |

| BH-E 0000XE-D2130Y | 3.06 | 2.93 | 0.80 | 1.03 |

| BH-E 0000XE-D2132Y | 3.17 | 0.72 | 0.60 | 1.58 |

| BH-E 0000XE-D2108Y | 3.18 | 2.37 | 0.80 | 1.59 |

| BH-E 0000XE-D2133Y | 3.18 | 1.03 | 1.00 | 1.59 |

| BH-E 0000XE-D2134Y | 3.18 | 1.26 | 1.02 | 1.59 |

| BH-E 0000XE-D2135Y | 3.50 | 1.25 | 0.80 | 1.75 |

| BH-E 0000XE-D2109Y | 3.92 | 1.96 | 1.10 | 1.96 |

| BH-E 0000XE-D2110Y | 4.78 | 2.39 | 1.20 | 2.39 |

| BH-E 0000XE-D2139Y | 4.75 | 2.38 | 1.27 | 2.37 |

| BH-E 0000XE-D2112Y | 5.26 | 2.63 | 1.57 | 2.63 |

| BH-E 0000XE-D2111Y | 5.26 | 2.12 | 1.27 | 2.63 |

| BH-E 0000XE-D2113Y | 5.94 | 3.39 | 1.10 | 2.97 |

| BH-E 0000XE-D2114Y | 6.35 | 3.18 | 0.50 | 3.18 |

| BH-E 0000XE-D2116Y | 7.92 | 3.96 | 1.57 | 3.96 |

| BH-E 0000XE-D2148Y | 8.00 | 2.00 | 0.80 | 4.00 |

| BH-E 0000XE-D2149Y | 8.00 | 4.00 | 2.00 | 4.00 |

| BH-E 0000XE-D2118Y | 8.00 | 5.00 | 1.00 | 4.00 |

| BH-E 0000XE-D2142Y | 8.00 | 8.00 | 2.00 | 4.00 |

| BH-E 0000XE-D2141Y | 9.50 | 6.40 | 1.25 | 4.75 |

| BH-E 0000XE-D2119Y | 9.50 | 1.65 | 1.25 | 4.75 |

| BH-E 0000XE-D2123Y | 10.00 | 2.00 | 1.40 | 5.00 |

| BH-E 0000XE-D2120Y | 10.00 | 8.00 | 2.00 | 5.00 |

| BH-E 0000XE-D2121Y | 10.70 | 5.05 | 1.00 | 5.35 |

| BH-E 0000XE-D2127Y | 10.60 | 5.40 | 1.00 | 5.30 |

| BH-E 0000XE-D2143Y | 12.37 | 1.82 | 1.00 | 6.18 |

Custom profiles on demand.

Possible profiles:

Width between 0.8mm and 13mm

Height between 0.8mm and 13mm

Thickness ≥0.3mm

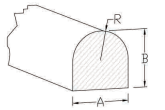

EMI shielding silicone gaskets with extruded conductive silicone : Solid D Type

References/Dimensions

| Référence | A (mm) | B (mm) | R (mm) |

| BH-E 0000XE-D1020Y | 0.85 | 1.90 | 0.43 |

| BH-E 0000XE-D1003Y | 0.90 | 1.33 | 0.45 |

| BH-E 0000XE-D1021Y | 1.00 | 2.00 | 0.50 |

| BH-E 0000XE-D1001Y | 1.40 | 1.60 | 0.70 |

| BH-E 0000XE-D1022Y | 1.45 | 1.60 | 0.73 |

| BH-E 0000XE-D1002Y | 1.57 | 1.73 | 0.78 |

| BH-E 0000XE-D1023Y | 1.57 | 2.16 | 0.78 |

| BH-E 0000XE-D1004Y | 1.57 | 2.54 | 0.78 |

| BH-E 0000XE-D1005Y | 1.59 | 1.75 | 0.79 |

| BH-E 0000XE-D1024Y | 1.73 | 1.60 | 0.87 |

| BH-E 0000XE-D1025Y | 1.73 | 2.60 | 0.87 |

| BH-E 0000XE-D1006Y | 1.90 | 4.50 | 0.95 |

| BH-E 0000XE-D1010Y | 1.98 | 2.26 | 0.99 |

| BH-E 0000XE-D1007Y | 1.98 | 2.39 | 0.99 |

| BH-E 0000XE-D1008Y | 2.00 | 2.00 | 1.00 |

| BH-E 0000XE-D1028Y | 2.00 | 1.78 | 1.00 |

| BH-E 0000XE-D1030Y | 2.03 | 2.80 | 1.01 |

| BH-E 0000XE-D1031Y | 2.30 | 2.35 | 1.15 |

| BH-E 0000XE-D1011Y | 2.39 | 1.98 | 1.19 |

| BH-E 0000XE-D1012Y | 2.39 | 2.39 | 1.19 |

| BH-E 0000XE-D1016Y | 2.50 | 1.60 | 1.25 |

| BH-E 0000XE-D1029Y | 2.50 | 2.20 | 1.25 |

| BH-E 0000XE-D1013Y | 2.60 | 2.90 | 1.30 |

| BH-E 0000XE-D1014Y | 2.77 | 3.17 | 1.38 |

| BH-E 0000XE-D1032Y | 3.00 | 3.90 | 1.50 |

| BH-E 0000XE-D1015Y | 3.10 | 3.43 | 1.55 |

| BH-E 0000XE-D1035Y | 3.18 | 3.96 | 1.59 |

| BH-E 0000XE-D1036Y | 3.78 | 2.78 | 1.89 |

| BH-E 0000XE-D1037Y | 3.92 | 3.92 | 1.96 |

| BH-E 0000XE-D1049Y | 4.52 | 4.43 | 2.26 |

| BH-E 0000XE-D1038Y | 4.78 | 4.78 | 2.39 |

| BH-E 0000XE-D1039Y | 5.26 | 4.75 | 2.63 |

| BH-E 0000XE-D1040Y | 5.26 | 5.26 | 2.63 |

| BH-E 0000XE-D1041Y | 5.94 | 6.36 | 2.97 |

| BH-E 0000XE-D1019Y | 6.35 | 6.35 | 3.17 |

| BH-E 0000XE-D1042Y | 6.45 | 6.35 | 3.23 |

| BH-E 0000XE-D1043Y | 7.92 | 7.92 | 3.96 |

| BH-E 0000XE-D1044Y | 8.00 | 9.00 | 4.00 |

| BH-E 0000XE-D1045Y | 9.50 | 6.40 | 4.75 |

| BH-E 0000XE-D1050Y | 10.00 | 7.00 | 5.00 |

| BH-E 0000XE-D1046Y | 10.00 | 13.00 | 5.00 |

| BH-E 0000XE-D1048Y | 10.60 | 10.70 | 5.30 |

| BH-E 0000XE-D1047Y | 10.70 | 10.40 | 5.35 |

Custom profile on demand

Possible profiles:

Width between 0.8mm and 13mm

Height between 0.8mm and 13mm

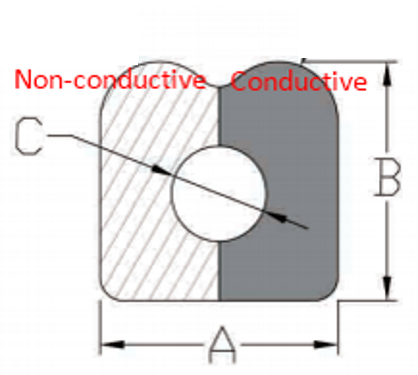

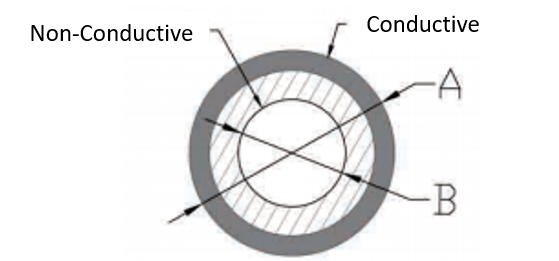

EMI shielding gaskets with bi-material silicone

The EMI shielding silicone gaskets with bi-material silicone (charged and neutral silicone) are mounted in grooves then compressed.

These EMI shielding joints are extruded using standard or custom profiles. They provide electromagnetic and fluid tightness (up to IP69).

Lear more about EMI shielding gaskets made from bi-material conductive silicone.

The bi-material EMI shielding gaskets ensure conductivity over the entire length of the joint in addition to high tightness against fluids (IP68 see IP69, subject to adequate groove sizing).

Bi-material EMI shielding gaskets are made of neutral silicone, or fluorosilicone (more resistant), and a silicone loaded with conductive particles (Ni/C or Ag/Al). These two materials are extruded simultaneously.

The filled silicone partially covers the joint section, which create a very flexible joint.

Different joint profiles are available, Compelma advises you on the profiles and grooves to define, according to your specifications.

This type of seal is very efficient in both IP sealing and shielding performance with excellent resistance over time.

Our range of bi-material seals is developed to resist corrosion and aging problems, particularly in aggressive environments: salt spray, electrolytic agents, oil, solvents, etc. Over temperature ranges from -55°C to +150°C.

If a specific extrusion profile is needed, we can design it. The extrusion profiles are guaranteed for life, so no need to worry about possible additional tooling costs.

The best way to find the best profile for your montage is to consult us!

We advise you for the best profile according to your groove or the best groove for a specific profile.

A project, a request?

EMI shielding gaskets with extruded bi-material silicone : M Type

References/Dimensions

| Référence | A (mm) | B (mm) | C (mm) |

| CCEFMT-2 | 1,60 | 1,95 | 0,60 |

| CCEFMT-1 | 1,65 | 1,63 | 0,50 |

| CCEFMT-3 | 1,85 | 2,00 | 0,90 |

| CCEFMT-4 | 2,00 | 2,10 | 0,90 |

| CCEFMT-5 | 2,10 | 2,10 | |

| CCEFMT-6 | 3,00 | 3,00 | 0,81 |

| CCEFMT-7 | 3,00 | 3,45 | 0,81 |

| CCEFMT-10 | 3,00 | 2,95 | 1,40 |

| CCEFMT-12 | 3,10 | 3,68 | 1,94 |

Custom extrusion/profile on demand

EMI shielding gaskets with extruded bi-material silicone : O type (Ultra Soft)

References/Dimensions

| Référence | A (mm) | B (mm) |

| CCESO-1 | 1,50 | |

| CCESO-2 | 1,87 | |

| CCESO-3 | 2,03 | |

| CCESO-4 | 3,20 | 1,00 |

| CCESO-5 | 3,96 | 2,36 |

| CCESO-6 | 6,30 | 4,30 |

Custom extrusion/profile on demand.