EMI/RFI shielded glass

Transparent conductive glass and film for EMI shielding of openings, screens or facades

EMI/RFI shielded glass or film is used to shield openings while maintaining visibility inside the equipment or on a screen.

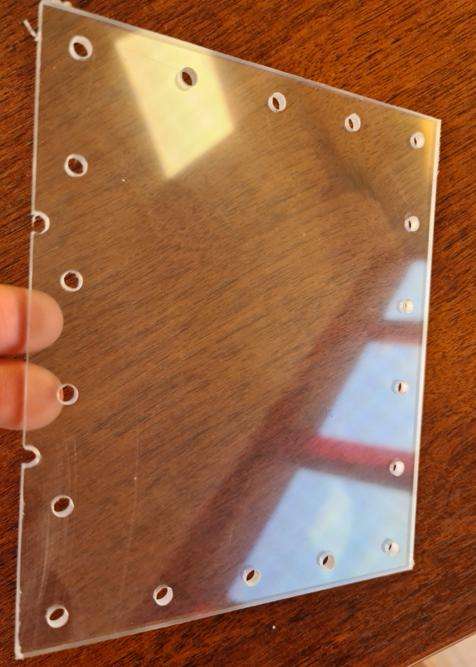

These EMI/RFI shielded glass can be made of glass or polycarbonate (other materials on request). Electrical conductivity is provided either by a metal mesh film (microscopic mesh) or by surface treatment (ITO type).

These EMI/RFI windows are made to measure for both small surfaces (moulded) and large openings (laminated film).

Contact us to find out which technology is best suited to your project. We can help you achieve the best performance/cost ratio.

EMI/RFI shielded glass, Key points :

- Transparency from 70% to over 90% light transmission

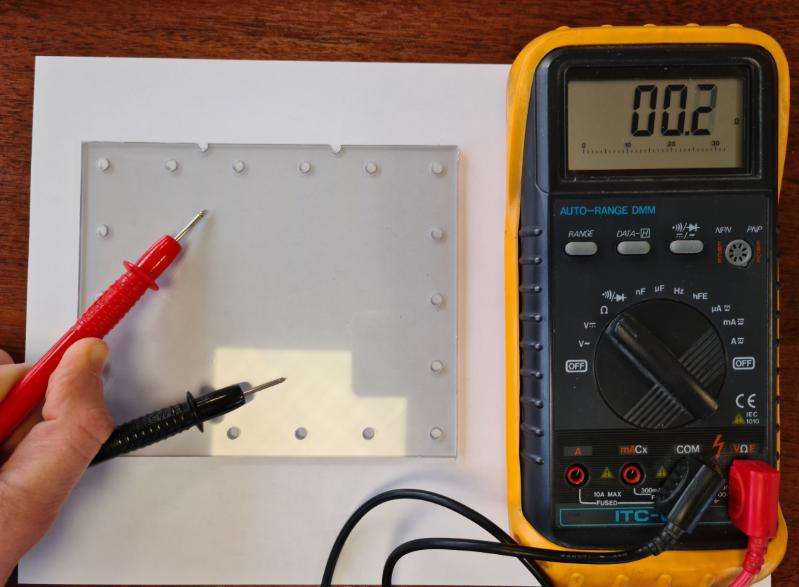

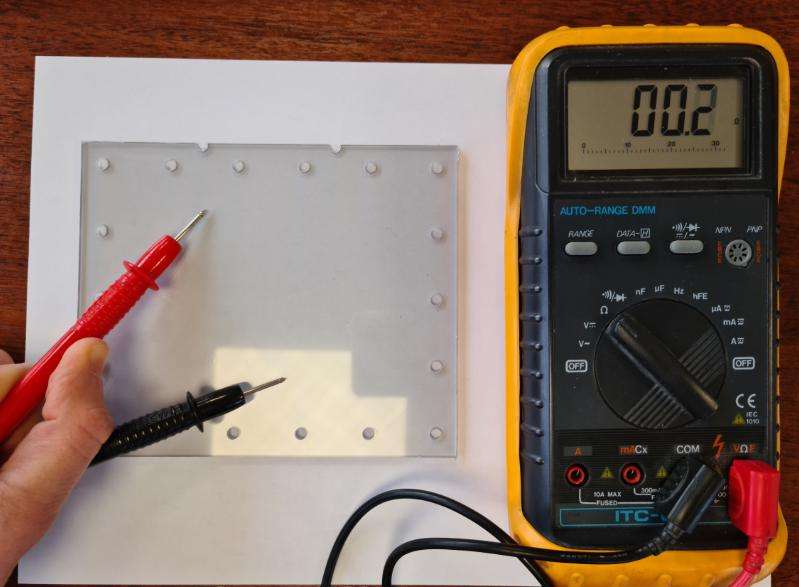

- Surface resistance from 15Ω/Square to less than 0.2Ω/Square

- EMI shielding >50dB (30MHz to 6GHz)

- Custom dimensions and machining

- Clean room manufacturing and systematic optical quality control

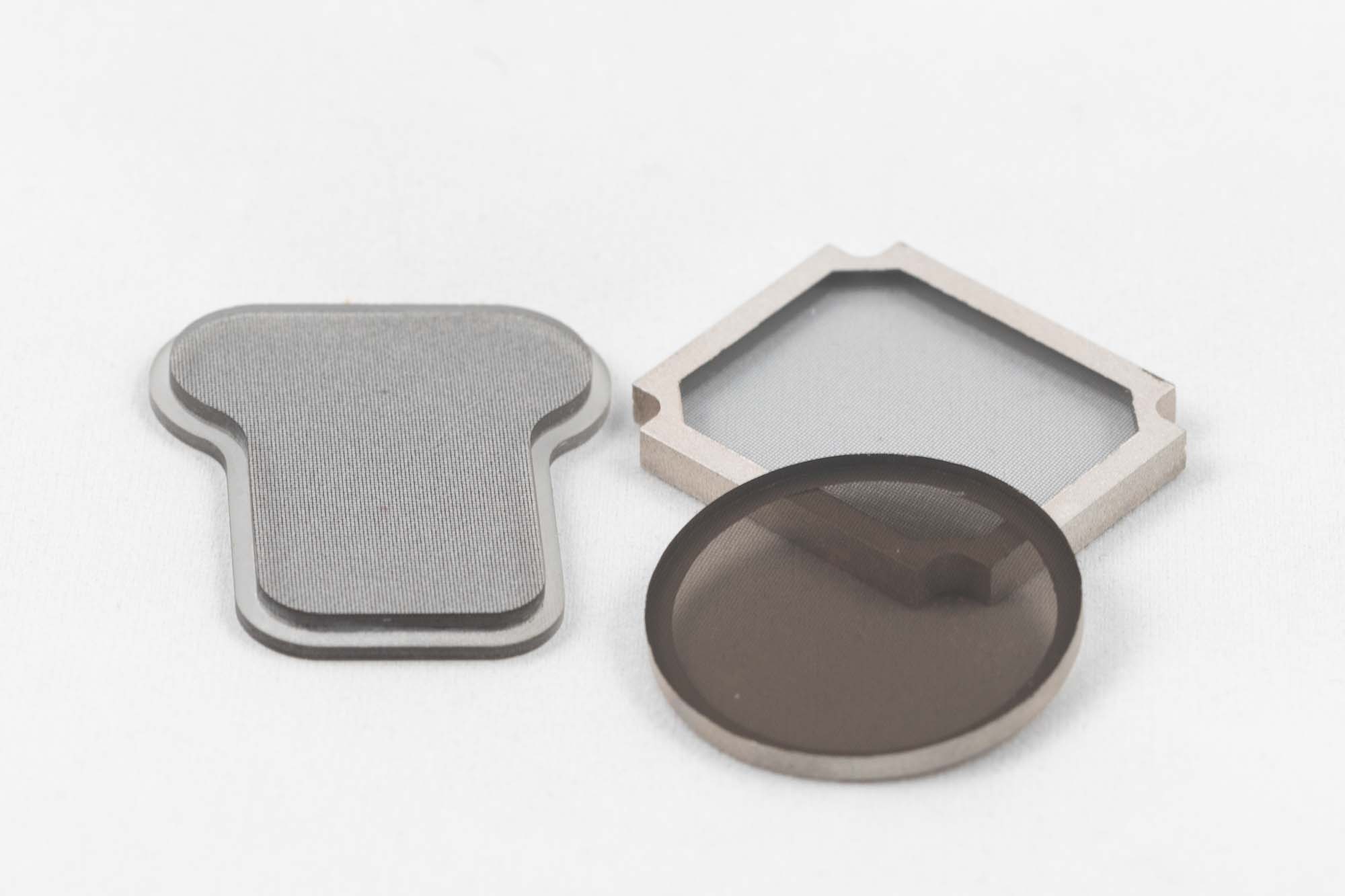

- Mesh molded into the glass for military and medical applications

- Prototypes and samples of EMI/RFI shielded glass on request.

About transparent EMI/RFI shielded glass

There are two main ways of creating a transparent EMI shielding window.

ITO Film

ITO film is a metallised PET film (a thin layer of metal is sprayed onto a layer of PET).

This EMI shielding technology is exposed to long-term oxidation due to the manufacturing process (the film may yellow or retain fingerprints).

ITO film for transparent EMI shielding has low EMI shielding performance (mainly above 10Ω/□). This level of EMI shielding can be problematic for demanding applications (such as military, RFID integration or medical projects).

ITO film is also mechanically fragile, so precautions must be taken during the lamination process.

This ITO film is however more economic.

Copper mesh

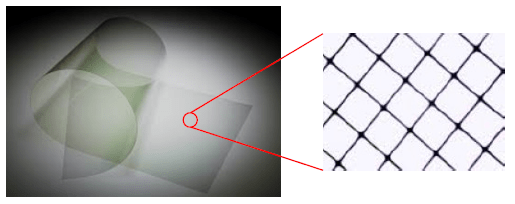

Cu Mesh Film is a photo-cut copper foil laminated onto a PET layer (total thickness 0.1mm).

Thanks to the conductivity of copper, this transparent EMI shielding film offers high performance (below 0.2Ω/□).

Its mechanical structure guarantees good mechanical properties and no breakage during the lamination process.

This film is manufactured in rolls 1,500 mm wide and several tens of metres long to cover large openings.

A microscopic manufacturing process using photoengraving

The manufacturing process for this transparent EMI shielding film has improved in recent years.

There is no longer any need for busbars or grounding strips, thanks to the high electrical conductivity at all points of the EMI shielding film.

Previous manufacturing processes required tooling costs for each size of EMI shielding glass. This is no longer the case. The film is laminated directly onto any substrate and in any size.

A protective layer is applied to the EMC shielding film to ensure a high level of protection against oxidation.

High transparency of the EMI/RFI shielded glass thanks to micro-mesh (>80% light transmission)

Transparency is a key issue when it comes to EMI and RF shielding for glass.

We are aware of this, and have worked to offer an aperture rate of less than 150 OPI (Openings per Inch), ensuring transparency of over 80%.

Using a photo-etching process to create this microscopic Cu Mesh, the result is only a light brown layer for an EMI shielding level of over 50 dB.

High surface conductivity thanks to copper material (<0.2 Ω)

Maintaining a high level of electrical conductivity while keeping transparency is the key challenge in proposing a transparent EMI shielding film for windows and openings.

The raw copper used to manufacture the EMI film ensures high electrical conductivity over the entire surface of the EMI/RFI shielding glass.

No need for busbars or grounding strips, thanks to the high electrical conductivity at every point of the EMI shielding glass.

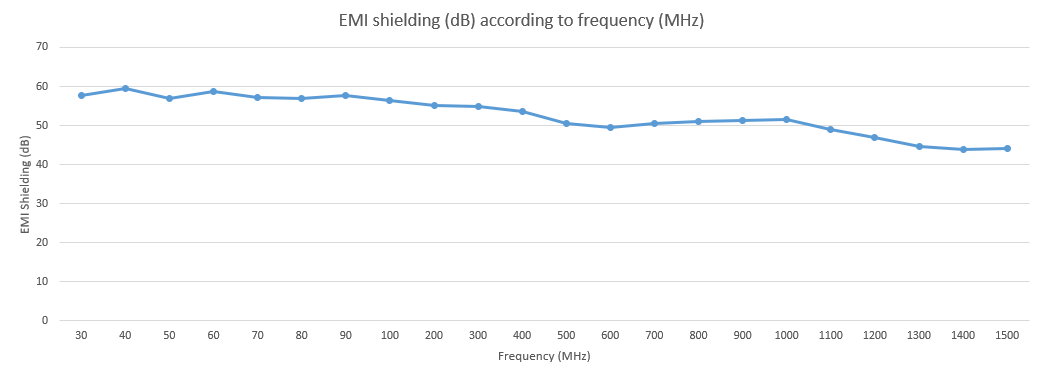

High level of EMI and RF shielding

The conductivity of copper ensures a high level of EMI shielding

Cu Mesh film provides electromagnetic shielding of over 50dB at the main EMI and RFI frequencies.

From 30 MHz to 6 GHz, the EMI loss is greater than 40 dB, and greater than 50 dB from 30 MHz to 1 GHz.

Proven effectiveness on demanding EMI shielding projects

This EMI/RFI shielded film is also used to make electrical equipment invisible during military operations (no electromagnetic detection by radar).

It is also used on medical premises to protect medical staff and equipment from electromagnetic fields.

This EMI shielding film is also widely used in industrial projects such as RFID inventory or in anechoic chambers.

Turnkey EMI/RFI shielded glass

We supply the film ready for use (laminated with optical adhesive).

We also offer turnkey EMI/RFI shielding glass. We laminate our film onto glass or polycarbonate substrates, ready for assembly.

The lamination process is carried out in clean rooms to ensure high optical quality and the absence of dust or defects on the EMI/RFI shielding glass.