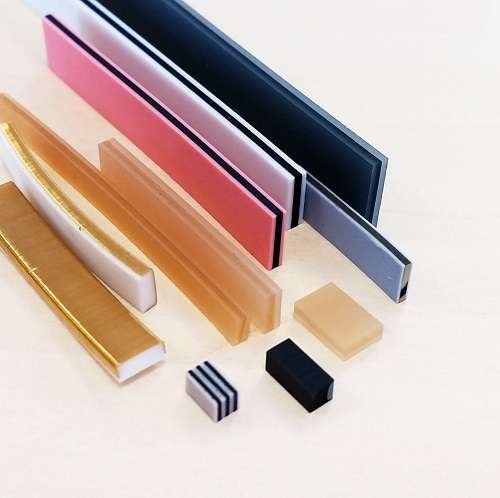

Elastomeric connectors (or zebra connectors)

Elastomeric connectors provide high connection density for electronic assembly (as LCD, sensors, etc).

Elastomeric connectors provide high-density connections. They can be made from either beryllium copper wire or conductive silicone (carbon).

These elastomeric connectors are integrated into electronic assemblies using holsters to control compression (no soldering required). They have excellent resistance to shocks and vibratory environments. No soldering or screwing is required.

We can customise these parts following your specifications.

Elastomeric connectors, Key points :

-

High connection density (pitch <0.1mm)

-

Good resistance to vibration and shock

-

No soldering required

-

Cost-effective interconnection solution

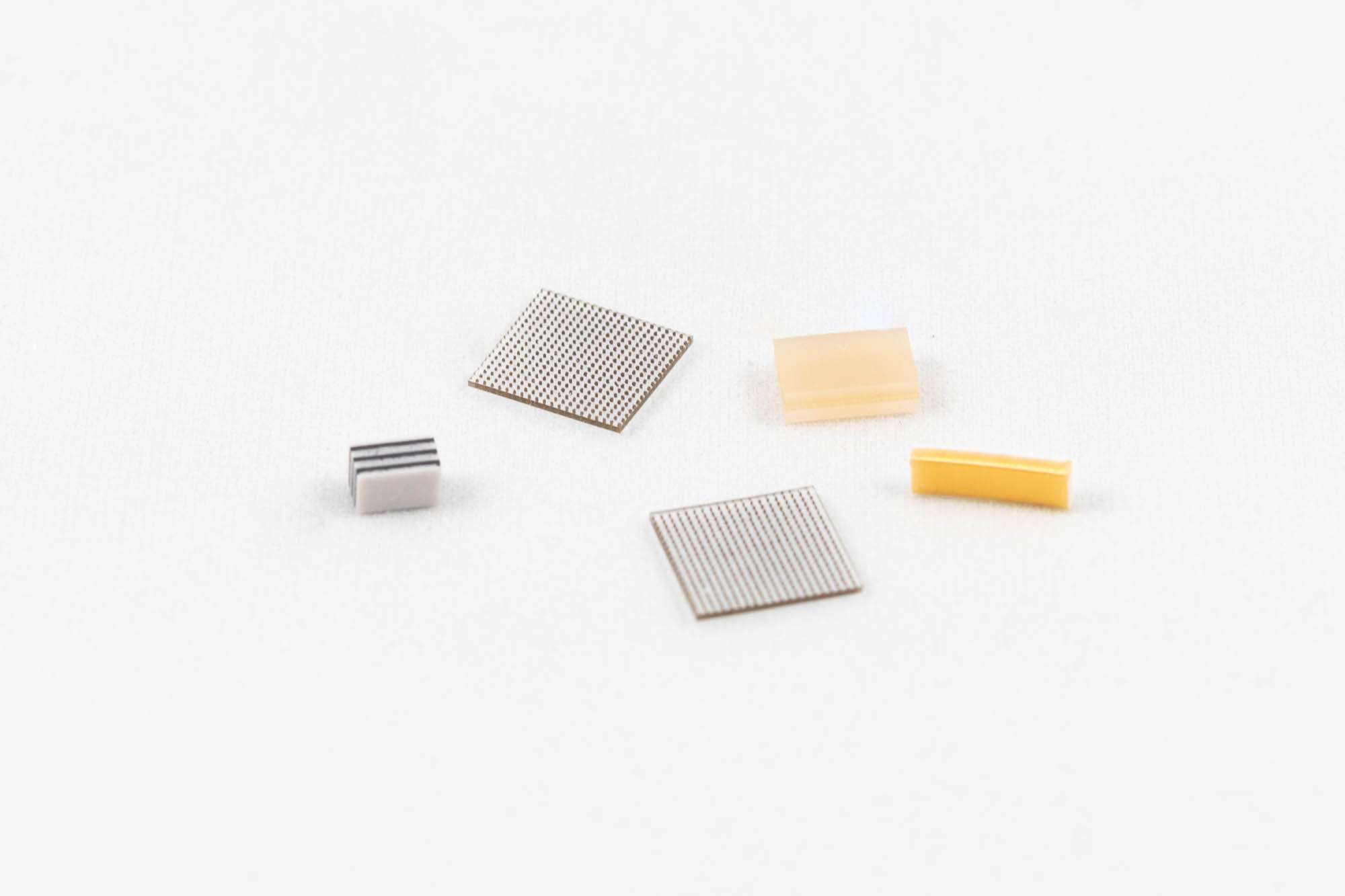

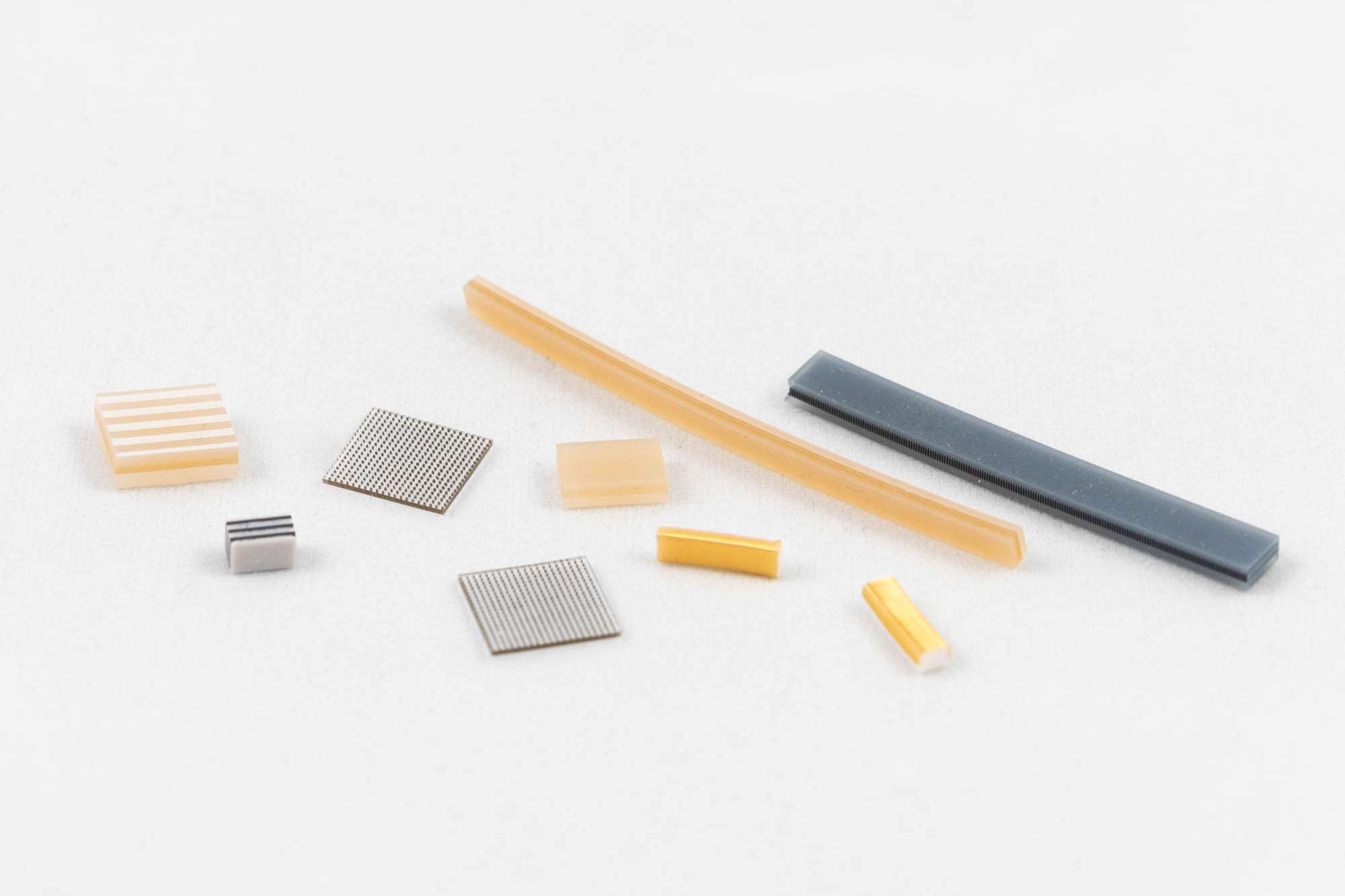

Connector pitches are standard. They are then custom-made (to size) to fit into your electronic assembly. We help you to choose the best dimension of elastomeric connectors following your project.

Prototypes and samples on request.

Description of elastomeric connectors

The elastomeric connector press-fits your electronic assemblies (board-to-board, display, component, microphone, BGA-type matrix component or other on PCB).

We offer design assistance in choosing the type of connector, pitch, dimensions, insulation, etc.

We also offer test supports for your electronic components and boards. We also supply ribbon cables to suit your design and requirements.