Thermal Interface Material (TIM) for heat transfer

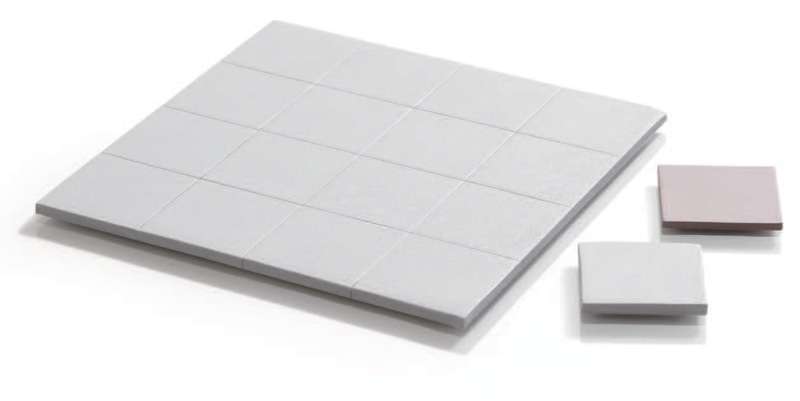

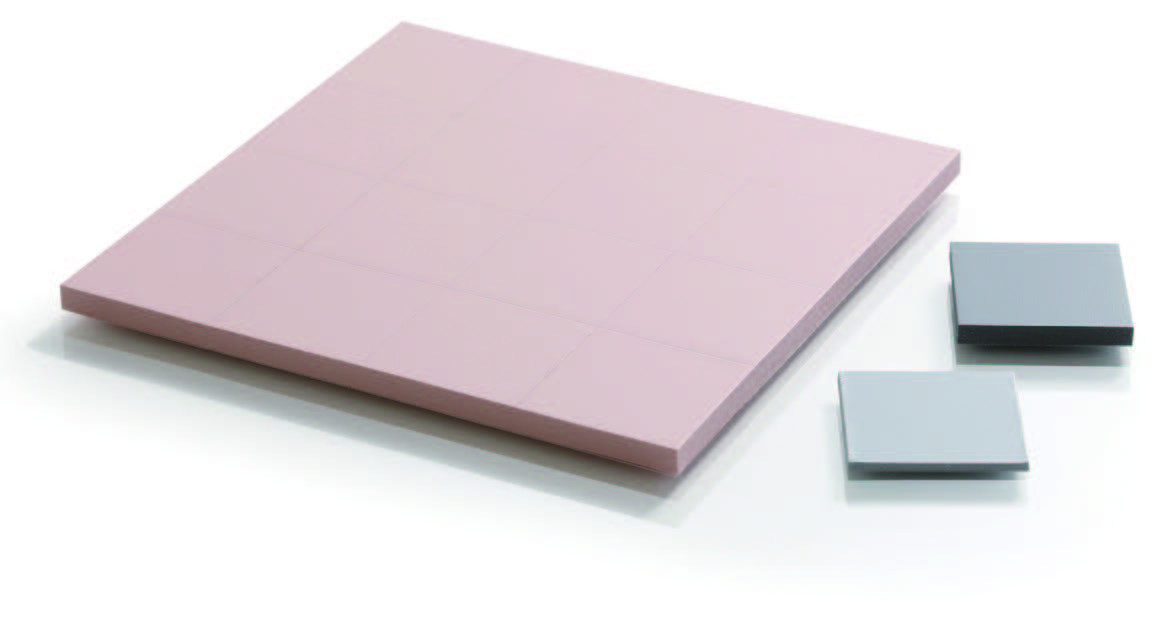

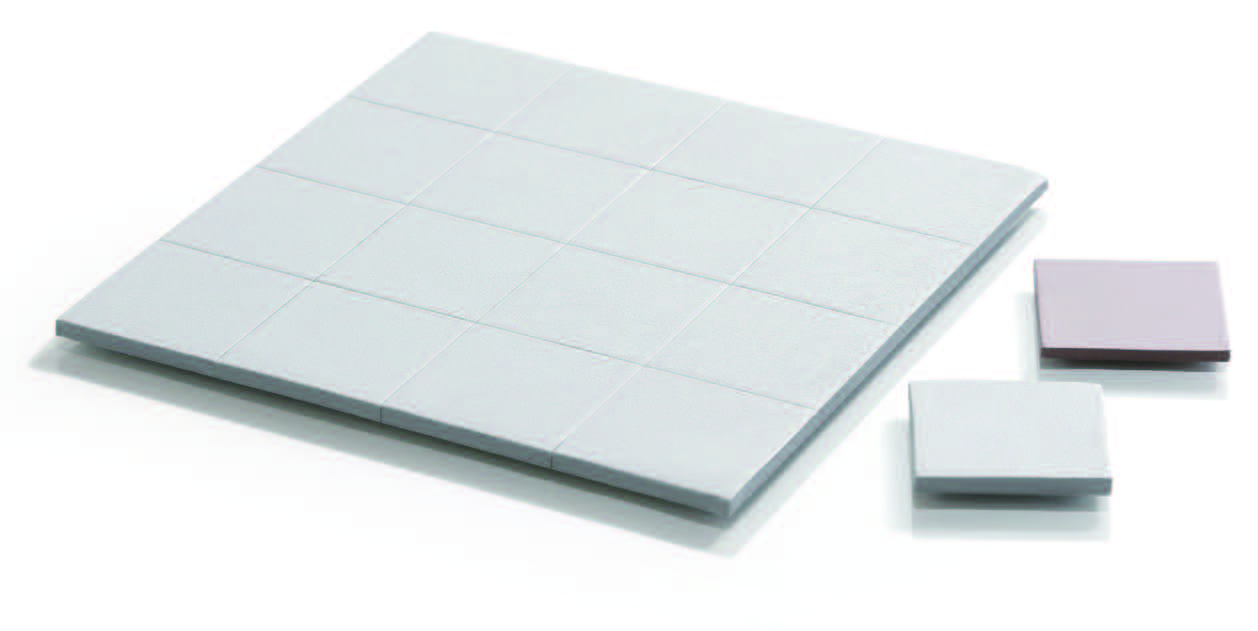

Thermal interface material, Gap fillers and thermal pads

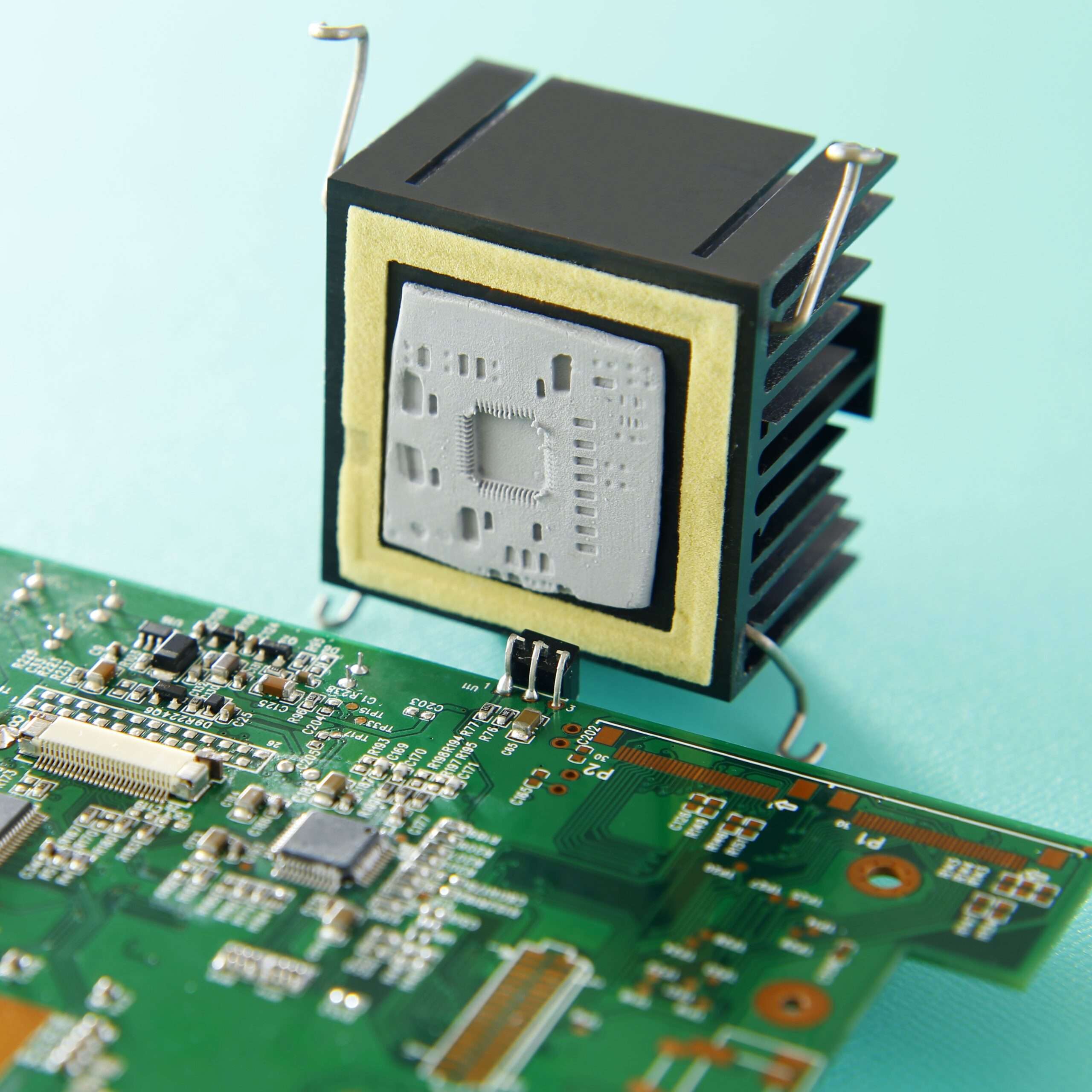

Thermal interface material makes complete heat transfer between the heat sources (component, CPU, GPU, etc.) and the heat sinks (or chassis) by replacing the air in the gaps between the assemblies. Without these thermal interface materials, heat transfer is very quickly limited and the component risks overheating or even destruction.

Compelma is the French representative of Fujipoly, a Japanese manufacturer of high quality thermal interfaces. We work with this manufacturer for the quality and performance of its products. We then cut the thermal interface material to size to deliver turnkey gap filler pads.

Thermal Interface Material, Key points :

-

Wide choice of interfaces available (hardness, thermal conductivity, thickness, etc.)

-

Cutting and shaping of thermal interface materials on request

-

Qualified interfaces for a wide range of projects (military, telecoms, industry, automotive)

-

Thermal conductivity up to 13W/m.K

-

Thicknesses from 0.1mm

-

Material laminations on request

-

Electrical insulation and protection of on-board components

Large catalogue of standard thermal interface materials available and customised materials available (dimensions, thickness, materials, thermal conductivity, etc.).

Detailed mechanical report supplied on request (dimensions, packaging, compression curves, thermal resistance, etc.).

Prototypes and samples of thermal interface material on request.

Thermal interface materials, thermal pads or gaps are a single name for these thermal interface materials.

The levels of performance, hardness, thickness and quality vary enormously on the market. That’s why we work with you to offer the most suitable materials to meet your specifications and to last the lifetime of your project.

Find out more about our thermal interface materials:

The thermal interface material avoid the layers of air (thermal insulation) between the components (CPU, GPU, processors) and the heat sinks.

The performance of thermal interface material (TIM) depends on the particle load of the silicone.

Compelma is Fujipoly’s European representative. For more information, please visit the website of our partner and expert Fujipoly on its SARCON® product range.

The interfaces are cut according to your drawings and packaged in sheets or reels according to their dimensions.

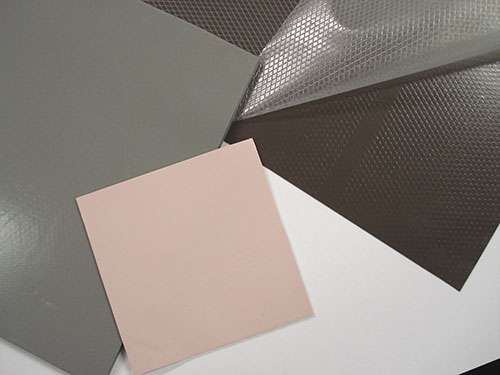

Our range comprises three main families: silicone-based, silicone-free and graphite.

-

Very flexible silicone base with thermal conductivity ≤17W/m.K These interfaces are made from a polymer matrix filled with thermally conductive particles. They conform perfectly to the geometries of a board’s components.

-

Silicone-free with a thermal conductivity ≤3W/m.K These interfaces are similar in functionality to silicone interfaces, but present no risk of outgassing or bleeding of silicone oil in sensitive environments (hard disks, optical components, etc.).

-

Graphite base with thermal conductivity ≤1500 W/m.K in the X,Y plane These thermal interfaces are available in natural or synthetic versions. These interfaces are suitable for thin thicknesses (a few tenths of a millimetre maximum). They can be laminated to metal parts (copper or aluminium) to increase the overall thermal performance.

Contact us to find the best solution for your project.

Catalogue of Thermal Interface Material (TIM)

(from Fujipoly, other materials on request)

Below are the thermal interface references we use most on our various projects.

For the full Fujipoly catalogue, click on the button.

The catalogue also contains all the compression curves, thermal conductivity, hardness, etc.

Cut to size and alternative materials on request

GR80A

Thermal conductivity : 8,0W/m.K

Thickness : 0,3 – 3,0 mm

Hardness : 75 Shore 00

Operating temp.(°C)

-40°C to +150°C

PG80B

Thermal conductivity : 8,0W/m.K

Thickness : 0,5 – 2,0 mm

Operating temp.(°C)

-40°C to +150°C

GR45A

Thermal conductivity : 4,5W/m.K

Thickness : 0,5 – 5,0 mm

Hardness : 50 Shore 00

Operating temp.(°C)

-40°C to +150°C

GR25A

Thermal conductivity : 2,5W/m.K

Thickness : 0,5 – 5,0 mm

Hardness : 50 Shore 00

Operating temp.(°C)

-40°C to +150°C

PG25A

Thermal conductivity : 2,5W/m.K

Thickness : 1,5 – 5,0 mm

Operating temp.(°C)

-40°C to +150°C

NR-c

Thermal conductivity : 1,3W/m.K

Thickness : 0,3 – 3,0 mm

Hardness : 53 Shore 00

Operating temp.(°C)

-40°C to +150°C